PDF Publication Title:

Text from PDF Page: 002

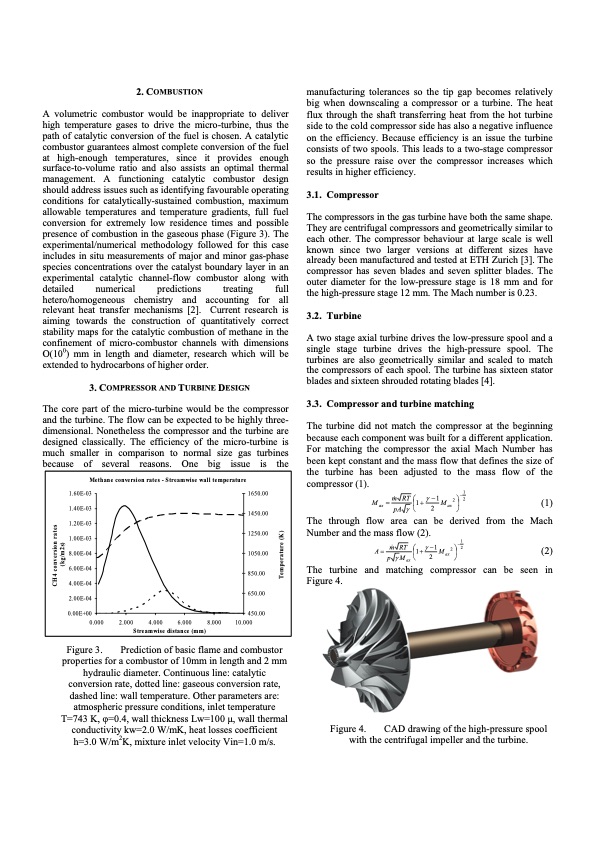

2. COMBUSTION A volumetric combustor would be inappropriate to deliver high temperature gases to drive the micro-turbine, thus the path of catalytic conversion of the fuel is chosen. A catalytic combustor guarantees almost complete conversion of the fuel at high-enough temperatures, since it provides enough surface-to-volume ratio and also assists an optimal thermal management. A functioning catalytic combustor design should address issues such as identifying favourable operating conditions for catalytically-sustained combustion, maximum allowable temperatures and temperature gradients, full fuel conversion for extremely low residence times and possible presence of combustion in the gaseous phase (Figure 3). The experimental/numerical methodology followed for this case includes in situ measurements of major and minor gas-phase species concentrations over the catalyst boundary layer in an experimental catalytic channel-flow combustor along with detailed numerical predictions treating full hetero/homogeneous chemistry and accounting for all relevant heat transfer mechanisms [2]. Current research is aiming towards the construction of quantitatively correct stability maps for the catalytic combustion of methane in the confinement of micro-combustor channels with dimensions O(100) mm in length and diameter, research which will be extended to hydrocarbons of higher order. 3. COMPRESSOR AND TURBINE DESIGN The core part of the micro-turbine would be the compressor and the turbine. The flow can be expected to be highly three- dimensional. Nonetheless the compressor and the turbine are designed classically. The efficiency of the micro-turbine is much smaller in comparison to normal size gas turbines because of several reasons. One big issue is the manufacturing tolerances so the tip gap becomes relatively big when downscaling a compressor or a turbine. The heat flux through the shaft transferring heat from the hot turbine side to the cold compressor side has also a negative influence on the efficiency. Because efficiency is an issue the turbine consists of two spools. This leads to a two-stage compressor so the pressure raise over the compressor increases which results in higher efficiency. 3.1. Compressor The compressors in the gas turbine have both the same shape. They are centrifugal compressors and geometrically similar to each other. The compressor behaviour at large scale is well known since two larger versions at different sizes have already been manufactured and tested at ETH Zurich [3]. The compressor has seven blades and seven splitter blades. The outer diameter for the low-pressure stage is 18 mm and for the high-pressure stage 12 mm. The Mach number is 0.23. 3.2. Turbine A two stage axial turbine drives the low-pressure spool and a single stage turbine drives the high-pressure spool. The turbines are also geometrically similar and scaled to match the compressors of each spool. The turbine has sixteen stator blades and sixteen shrouded rotating blades [4]. 3.3. Compressor and turbine matching The turbine did not match the compressor at the beginning because each component was built for a different application. For matching the compressor the axial Mach Number has been kept constant and the mass flow that defines the size of the turbine has been adjusted to the mass flow of the compressor (1). m&RT⎛γ−1 2⎞−12 Max=pAγ⎜⎝1+ 2 Max ⎟⎠ (1) The through flow area can be derived from the Mach Number and the mass flow (2). m&RT⎛γ−1 2⎞−12 A= p γM ⎜⎝1+ 2 Max ⎟⎠ (2) ax The turbine and matching compressor can be seen in Figure 4. Methane conversion rates - Streamwise wall temperature 1.60E-03 1.40E-03 1.20E-03 1.00E-03 8.00E-04 6.00E-04 4.00E-04 2.00E-04 0.00E+00 0.000 2.000 4.000 6.000 8.000 1650.00 1450.00 1250.00 1050.00 850.00 650.00 450.00 10.000 Streamwise distance (mm) Figure 3. properties for a combustor of 10mm in length and 2 mm Prediction of basic flame and combustor hydraulic diameter. Continuous line: catalytic conversion rate, dotted line: gaseous conversion rate, dashed line: wall temperature. Other parameters are: atmospheric pressure conditions, inlet temperature T=743 K, φ=0.4, wall thickness Lw=100 μ, wall thermal conductivity kw=2.0 W/mK, heat losses coefficient h=3.0 W/m2K, mixture inlet velocity Vin=1.0 m/s. Figure 4. with the centrifugal impeller and the turbine. CAD drawing of the high-pressure spool CH4 conversion rates (kg/m2s) Temperature (K)PDF Image | Ultra-High-Energy-Density Converter for Portable Power

PDF Search Title:

Ultra-High-Energy-Density Converter for Portable PowerOriginal File Name Searched:

schneider_PowerMEMS05.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |