PDF Publication Title:

Text from PDF Page: 004

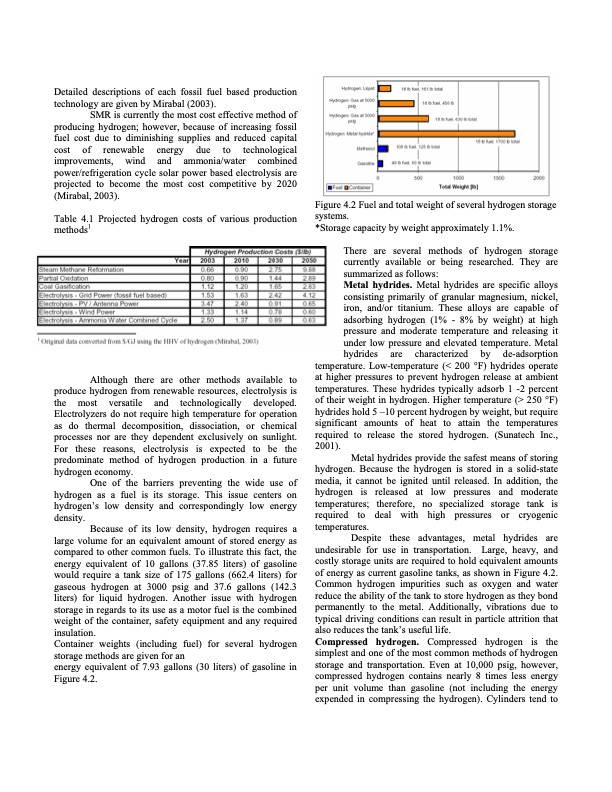

Detailed descriptions of each fossil fuel based production technology are given by Mirabal (2003). SMR is currently the most cost effective method of producing hydrogen; however, because of increasing fossil fuel cost due to diminishing supplies and reduced capital cost of renewable energy due to technological improvements, wind and ammonia/water combined power/refrigeration cycle solar power based electrolysis are projected to become the most cost competitive by 2020 (Mirabal, 2003). Table 4.1 Projected hydrogen costs of various production methods1 Figure 4.2 Fuel and total weight of several hydrogen storage systems. *Storage capacity by weight approximately 1.1%. There are several methods of hydrogen storage currently available or being researched. They are summarized as follows: Metal hydrides. Metal hydrides are specific alloys consisting primarily of granular magnesium, nickel, iron, and/or titanium. These alloys are capable of adsorbing hydrogen (1% - 8% by weight) at high pressure and moderate temperature and releasing it under low pressure and elevated temperature. Metal hydrides are characterized by de-adsorption temperature. Low-temperature (< 200 °F) hydrides operate at higher pressures to prevent hydrogen release at ambient temperatures. These hydrides typically adsorb 1 -2 percent of their weight in hydrogen. Higher temperature (> 250 °F) hydrides hold 5 –10 percent hydrogen by weight, but require significant amounts of heat to attain the temperatures required to release the stored hydrogen. (Sunatech Inc., 2001). Metal hydrides provide the safest means of storing hydrogen. Because the hydrogen is stored in a solid-state media, it cannot be ignited until released. In addition, the hydrogen is released at low pressures and moderate temperatures; therefore, no specialized storage tank is required to deal with high pressures or cryogenic temperatures. Despite these advantages, metal hydrides are undesirable for use in transportation. Large, heavy, and costly storage units are required to hold equivalent amounts of energy as current gasoline tanks, as shown in Figure 4.2. Common hydrogen impurities such as oxygen and water reduce the ability of the tank to store hydrogen as they bond permanently to the metal. Additionally, vibrations due to typical driving conditions can result in particle attrition that also reduces the tank’s useful life. Compressed hydrogen. Compressed hydrogen is the simplest and one of the most common methods of hydrogen storage and transportation. Even at 10,000 psig, however, compressed hydrogen contains nearly 8 times less energy per unit volume than gasoline (not including the energy expended in compressing the hydrogen). Cylinders tend to Although there are other methods available to produce hydrogen from renewable resources, electrolysis is the most versatile and technologically developed. Electrolyzers do not require high temperature for operation as do thermal decomposition, dissociation, or chemical processes nor are they dependent exclusively on sunlight. For these reasons, electrolysis is expected to be the predominate method of hydrogen production in a future hydrogen economy. One of the barriers preventing the wide use of hydrogen as a fuel is its storage. This issue centers on hydrogen’s low density and correspondingly low energy density. Because of its low density, hydrogen requires a large volume for an equivalent amount of stored energy as compared to other common fuels. To illustrate this fact, the energy equivalent of 10 gallons (37.85 liters) of gasoline would require a tank size of 175 gallons (662.4 liters) for gaseous hydrogen at 3000 psig and 37.6 gallons (142.3 liters) for liquid hydrogen. Another issue with hydrogen storage in regards to its use as a motor fuel is the combined weight of the container, safety equipment and any required insulation. Container weights (including fuel) for several hydrogen storage methods are given for an energy equivalent of 7.93 gallons (30 liters) of gasoline in Figure 4.2.PDF Image | Optimization of a Scroll Expander Applied to an Ammonia/Water Combined Cycle System for Hydrogen Production - Paper No. 1645

PDF Search Title:

Optimization of a Scroll Expander Applied to an Ammonia/Water Combined Cycle System for Hydrogen Production - Paper No. 1645Original File Name Searched:

ScrollExpander.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |