PDF Publication Title:

Text from PDF Page: 003

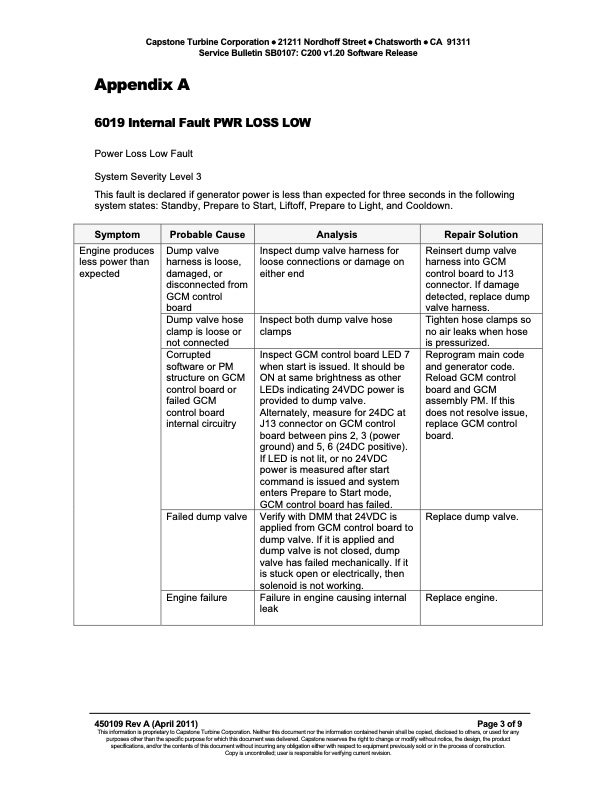

Capstone Turbine Corporation 21211 Nordhoff Street Chatsworth CA 91311 Service Bulletin SB0107: C200 v1.20 Software Release Appendix A 6019 Internal Fault PWR LOSS LOW Power Loss Low Fault System Severity Level 3 This fault is declared if generator power is less than expected for three seconds in the following system states: Standby, Prepare to Start, Liftoff, Prepare to Light, and Cooldown. Symptom Probable Cause Analysis Repair Solution Dump valve harness is loose, damaged, or disconnected from GCM control board Inspect dump valve harness for loose connections or damage on either end Reinsert dump valve harness into GCM control board to J13 connector. If damage detected, replace dump valve harness. Engine produces less power than expected Dump valve hose clamp is loose or not connected Inspect both dump valve hose clamps Tighten hose clamps so no air leaks when hose is pressurized. Corrupted software or PM structure on GCM control board or failed GCM control board internal circuitry Inspect GCM control board LED 7 when start is issued. It should be ON at same brightness as other LEDs indicating 24VDC power is provided to dump valve. Alternately, measure for 24DC at J13 connector on GCM control board between pins 2, 3 (power ground) and 5, 6 (24DC positive). If LED is not lit, or no 24VDC power is measured after start command is issued and system enters Prepare to Start mode, GCM control board has failed. Reprogram main code and generator code. Reload GCM control board and GCM assembly PM. If this does not resolve issue, replace GCM control board. Failed dump valve Verify with DMM that 24VDC is applied from GCM control board to dump valve. If it is applied and dump valve is not closed, dump valve has failed mechanically. If it is stuck open or electrically, then solenoid is not working. Replace dump valve. Engine failure Failure in engine causing internal leak Replace engine. Page 3 of 9 450109 Rev A (April 2011) This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction. Copy is uncontrolled; user is responsible for verifying current revision.PDF Image | Capstone Technical Support C200 v1.20 Software Release

PDF Search Title:

Capstone Technical Support C200 v1.20 Software ReleaseOriginal File Name Searched:

SB0107_C200_v120_Software_Release.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |