PDF Publication Title:

Text from PDF Page: 002

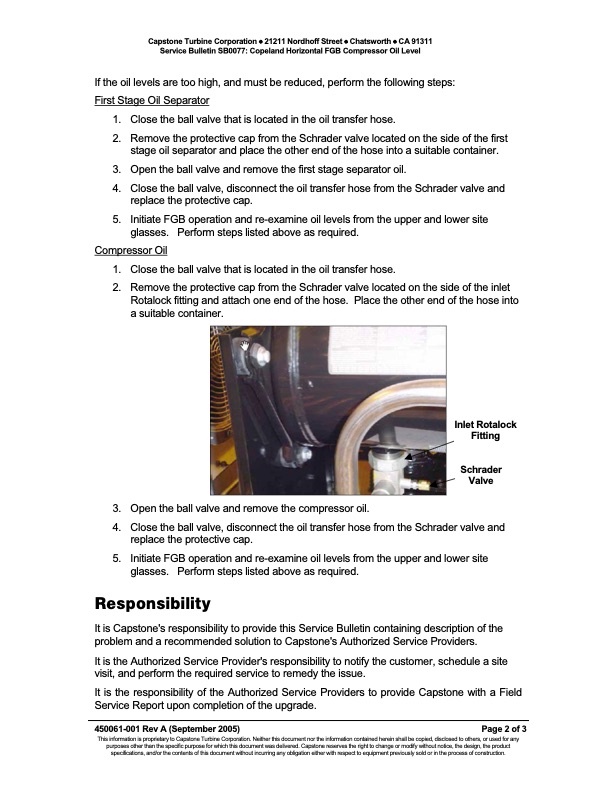

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 Service Bulletin SB0077: Copeland Horizontal FGB Compressor Oil Level If the oil levels are too high, and must be reduced, perform the following steps: First Stage Oil Separator 1. Close the ball valve that is located in the oil transfer hose. 2. Remove the protective cap from the Schrader valve located on the side of the first stage oil separator and place the other end of the hose into a suitable container. 3. Open the ball valve and remove the first stage separator oil. 4. Close the ball valve, disconnect the oil transfer hose from the Schrader valve and replace the protective cap. 5. Initiate FGB operation and re-examine oil levels from the upper and lower site glasses. Perform steps listed above as required. Compressor Oil 1. Close the ball valve that is located in the oil transfer hose. 2. Remove the protective cap from the Schrader valve located on the side of the inlet Rotalock fitting and attach one end of the hose. Place the other end of the hose into a suitable container. Inlet Rotalock Fitting Schrader Valve 3. Open the ball valve and remove the compressor oil. 4. Close the ball valve, disconnect the oil transfer hose from the Schrader valve and replace the protective cap. 5. Initiate FGB operation and re-examine oil levels from the upper and lower site glasses. Perform steps listed above as required. Responsibility It is Capstone's responsibility to provide this Service Bulletin containing description of the problem and a recommended solution to Capstone's Authorized Service Providers. It is the Authorized Service Provider's responsibility to notify the customer, schedule a site visit, and perform the required service to remedy the issue. It is the responsibility of the Authorized Service Providers to provide Capstone with a Field Service Report upon completion of the upgrade. 450061-001 Rev A (September 2005) Page 2 of 3 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | All Copeland Horizontal Fuel Gas Boosters (FGB) compressor oil level

PDF Search Title:

All Copeland Horizontal Fuel Gas Boosters (FGB) compressor oil levelOriginal File Name Searched:

SB0077_Compressor_Oil_Level.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |