PDF Publication Title:

Text from PDF Page: 010

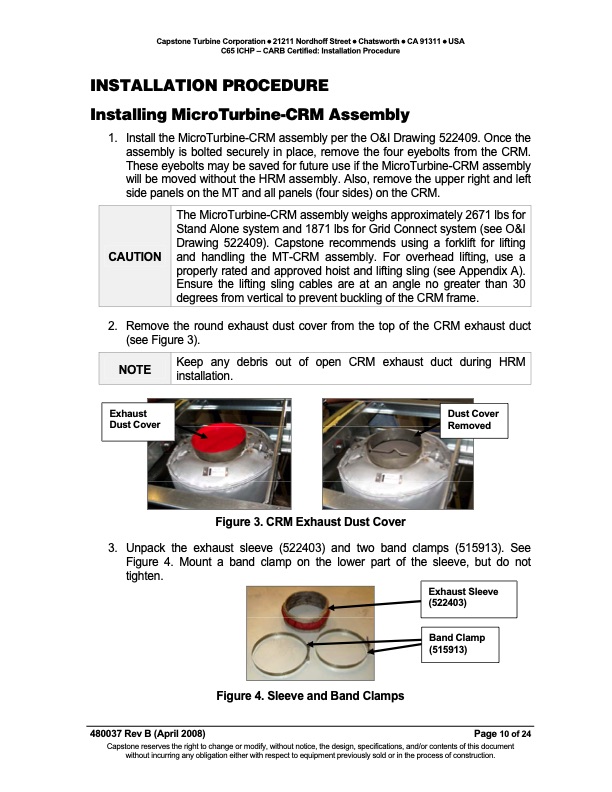

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA C65 ICHP – CARB Certified: Installation Procedure INSTALLATION PROCEDURE Installing MicroTurbine-CRM Assembly 1. InstalltheMicroTurbine-CRMassemblypertheO&IDrawing522409.Oncethe assembly is bolted securely in place, remove the four eyebolts from the CRM. These eyebolts may be saved for future use if the MicroTurbine-CRM assembly will be moved without the HRM assembly. Also, remove the upper right and left side panels on the MT and all panels (four sides) on the CRM. CAUTION The MicroTurbine-CRM assembly weighs approximately 2671 lbs for Stand Alone system and 1871 lbs for Grid Connect system (see O&I Drawing 522409). Capstone recommends using a forklift for lifting and handling the MT-CRM assembly. For overhead lifting, use a properly rated and approved hoist and lifting sling (see Appendix A). Ensure the lifting sling cables are at an angle no greater than 30 degrees from vertical to prevent buckling of the CRM frame. 2. Remove the round exhaust dust cover from the top of the CRM exhaust duct (see Figure 3). NOTE Keep any debris out of open CRM exhaust duct during HRM installation. Figure 3. CRM Exhaust Dust Cover Exhaust Dust Cover Dust Cover Removed 3. Unpack the exhaust sleeve (522403) and two band clamps (515913). See Figure 4. Mount a band clamp on the lower part of the sleeve, but do not tighten. Exhaust Sleeve (522403) Band Clamp (515913) Figure 4. Sleeve and Band Clamps 480037 Rev B (April 2008) Page 10 of 24 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | C65 ICHP – CARB CERTIFIED INSTALLATION PROCEDURE

PDF Search Title:

C65 ICHP – CARB CERTIFIED INSTALLATION PROCEDUREOriginal File Name Searched:

480037B_C65_ICHP-CARB_Installation.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |