PDF Publication Title:

Text from PDF Page: 011

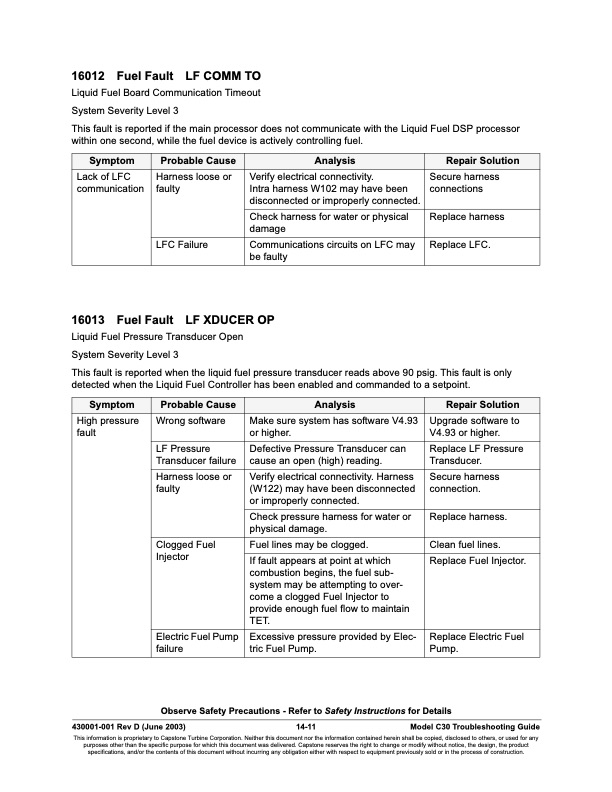

16012 Fuel Fault LF COMM TO Liquid Fuel Board Communication Timeout System Severity Level 3 This fault is reported if the main processor does not communicate with the Liquid Fuel DSP processor within one second, while the fuel device is actively controlling fuel. Symptom Probable Cause Analysis Repair Solution Lack of LFC communication Harness loose or faulty Verify electrical connectivity. Intra harness W102 may have been disconnected or improperly connected. Secure harness connections Check harness for water or physical damage Replace harness LFC Failure Communications circuits on LFC may be faulty Replace LFC. 16013 Fuel Fault LF XDUCER OP Liquid Fuel Pressure Transducer Open System Severity Level 3 This fault is reported when the liquid fuel pressure transducer reads above 90 psig. This fault is only detected when the Liquid Fuel Controller has been enabled and commanded to a setpoint. Symptom Probable Cause Analysis Repair Solution High pressure fault Wrong software Make sure system has software V4.93 or higher. Upgrade software to V4.93 or higher. LF Pressure Transducer failure Defective Pressure Transducer can cause an open (high) reading. Replace LF Pressure Transducer. Harness loose or faulty Verify electrical connectivity. Harness (W122) may have been disconnected or improperly connected. Secure harness connection. Check pressure harness for water or physical damage. Replace harness. Clogged Fuel Injector Fuel lines may be clogged. Clean fuel lines. If fault appears at point at which combustion begins, the fuel sub- system may be attempting to over- come a clogged Fuel Injector to provide enough fuel flow to maintain TET. Replace Fuel Injector. Electric Fuel Pump failure Excessive pressure provided by Elec- tric Fuel Pump. Replace Electric Fuel Pump. Observe Safety Precautions - Refer to Safety Instructions for Details 430001-001 Rev D (June 2003) 14-11 Model C30 Troubleshooting Guide This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Overview SERIES 16000 FAULT CODES Liquid Fuel Controller Faults

PDF Search Title:

Overview SERIES 16000 FAULT CODES Liquid Fuel Controller FaultsOriginal File Name Searched:

14_16000 Faults.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |