PDF Publication Title:

Text from PDF Page: 003

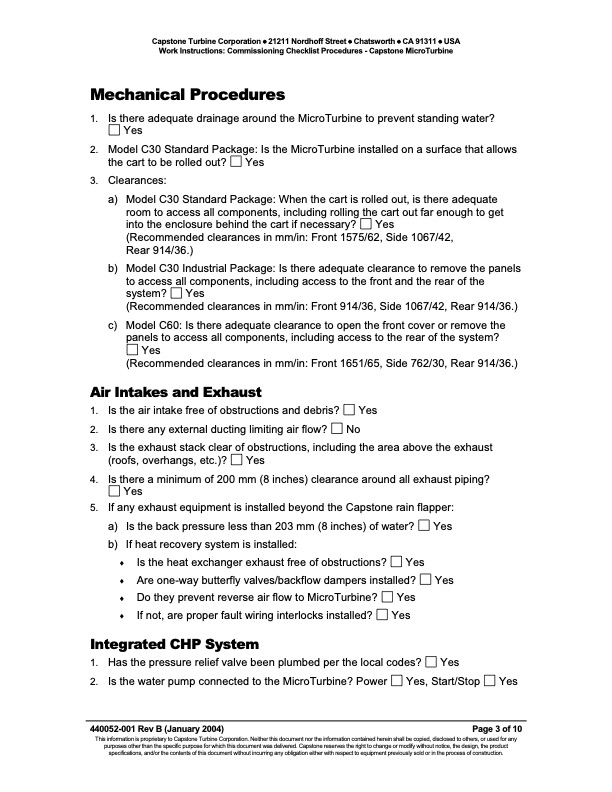

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Work Instructions: Commissioning Checklist Procedures - Capstone MicroTurbine Mechanical Procedures 1. Is there adequate drainage around the MicroTurbine to prevent standing water? Yes 2. Model C30 Standard Package: Is the MicroTurbine installed on a surface that allows the cart to be rolled out? Yes 3. Clearances: a) Model C30 Standard Package: When the cart is rolled out, is there adequate room to access all components, including rolling the cart out far enough to get into the enclosure behind the cart if necessary? Yes (Recommended clearances in mm/in: Front 1575/62, Side 1067/42, Rear 914/36.) b) Model C30 Industrial Package: Is there adequate clearance to remove the panels to access all components, including access to the front and the rear of the system? Yes (Recommended clearances in mm/in: Front 914/36, Side 1067/42, Rear 914/36.) c) Model C60: Is there adequate clearance to open the front cover or remove the panels to access all components, including access to the rear of the system? Yes (Recommended clearances in mm/in: Front 1651/65, Side 762/30, Rear 914/36.) Air Intakes and Exhaust 1. Is the air intake free of obstructions and debris? Yes 2. Is there any external ducting limiting air flow? No 3. Is the exhaust stack clear of obstructions, including the area above the exhaust (roofs, overhangs, etc.)? Yes 4. Is there a minimum of 200 mm (8 inches) clearance around all exhaust piping? Yes 5. If any exhaust equipment is installed beyond the Capstone rain flapper: a) b) ♦ ♦ ♦ ♦ Is the back pressure less than 203 mm (8 inches) of water? Yes If heat recovery system is installed: Is the heat exchanger exhaust free of obstructions? Yes Are one-way butterfly valves/backflow dampers installed? Yes Do they prevent reverse air flow to MicroTurbine? Yes If not, are proper fault wiring interlocks installed? Yes Integrated CHP System 1. Has the pressure relief valve been plumbed per the local codes? Yes 2. Is the water pump connected to the MicroTurbine? Power Yes, Start/Stop Yes 440052-001 Rev B (January 2004) Page 3 of 10 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Work Instructions Commissioning Checklist Procedures Capstone MicroTurbine

PDF Search Title:

Work Instructions Commissioning Checklist Procedures Capstone MicroTurbineOriginal File Name Searched:

440052_Comm_Procedures_WI.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |