PDF Publication Title:

Text from PDF Page: 002

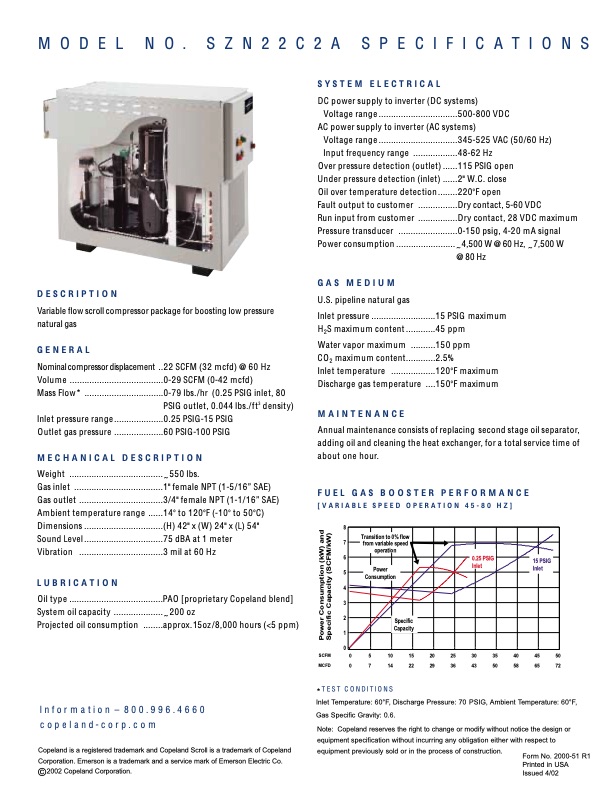

MODEL NO. SZN22C2A SPECIFICATIONS DESCRIPTION Variable flow scroll compressor package for boosting low pressure natural gas GENERAL Nominal compressor displacement ..22 SCFM (32 mcfd) @ 60 Hz Volume ......................................0-29 SCFM (0-42 mcfd) Mass Flow* ................................0-79 lbs./hr (0.25 PSIG inlet, 80 PSIG outlet, 0.044 lbs./ft3 density) Inlet pressure range....................0.25 PSIG-15 PSIG Outlet gas pressure ....................60 PSIG-100 PSIG MECHANICAL DESCRIPTION Weight ......................................~550 lbs. Gas inlet ....................................1" female NPT (1-5/16” SAE) Gas outlet ..................................3/4" female NPT (1-1/16” SAE) Ambient temperature range ......14° to 120°F (-10° to 50°C) Dimensions ................................(H) 42" x (W) 24" x (L) 54" Sound Level ................................75 dBA at 1 meter Vibration ..................................3 mil at 60 Hz LUBRICATION Oil type ......................................PAO [proprietary Copeland blend] System oil capacity ....................~200 oz Projectedoilconsumption ........approx.15oz/8,000hours(<5ppm) Information – 800.996.4660 copeland-corp.com Copeland is a registered trademark and Copeland Scroll is a trademark of Copeland Corporation. Emerson is a trademark and a service mark of Emerson Electric Co. ©2002 Copeland Corporation. GAS MEDIUM U.S. pipeline natural gas SYSTEM ELECTRICAL DC power supply to inverter (DC systems) Voltage range ................................500-800 VDC AC power supply to inverter (AC systems) Voltage range ................................345-525 VAC (50/60 Hz) Input frequency range ..................48-62 Hz Over pressure detection (outlet) ......115 PSIG open Under pressure detection (inlet) ......2" W.C. close Oil over temperature detection........220°F open Fault output to customer ................Dry contact, 5-60 VDC Run input from customer ................Dry contact, 28 VDC maximum Pressuretransducer ........................0-150psig,4-20mAsignal Power consumption ........................~4,500 W @ 60 Hz, ~7,500 W Inlet pressure ..........................15 PSIG maximum H2S maximum content ............45 ppm Watervapormaximum ..........150ppm CO2 maximum content............2.5% Inlettemperature ..................120°Fmaximum Discharge gas temperature ....150°F maximum MAINTENANCE Annual maintenance consists of replacing second stage oil separator, adding oil and cleaning the heat exchanger, for a total service time of about one hour. FUEL GAS BOOSTER PERFORMANCE [VARIABLE SPEED OPERATION 45-80 HZ] Variable Speed Operation: 45-80 Hz 8 7 6 5 4 3 2 1 0 @80Hz Transition to 0% flow from variable speed operation Power Consumption 0.25 PSIG Inlet 15 PSIG Inlet Specific Capacity SCFM MCFD 0 5 10 15 20 25 30 35 40 45 50 0 7 14 22 29 36 43 50 58 65 72 *TEST CONDITIONS Inlet Temperature: 60°F, Discharge Pressure: 70 PSIG, Ambient Temperature: 60°F, Gas Specific Gravity: 0.6. Note: Copeland reserves the right to change or modify without notice the design or equipment specification without incurring any obligation either with respect to equipment previously sold or in the process of construction. Form No. 2000-51 R1 Printed in USA Issued 4/02 Power Consumption (kW) and Specific Capacity (SCFM/kW)PDF Image | COPELAND SCROLL FUEL GAS BOOSTER

PDF Search Title:

COPELAND SCROLL FUEL GAS BOOSTEROriginal File Name Searched:

Copeland-2000-51-FGB-SpecSheet.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |