PDF Publication Title:

Text from PDF Page: 001

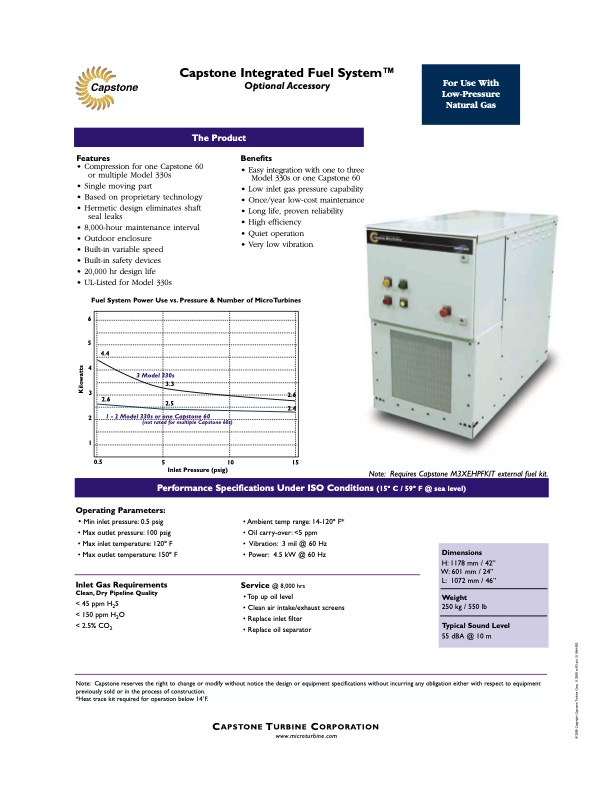

Features • Compression for one Capstone 60 or multiple Model 330s • Single moving part • Based on proprietary technology • Hermetic design eliminates shaft seal leaks • 8,000-hour maintenance interval • Outdoor enclosure • Built-in variable speed • Built-in safety devices • 20,000 hr design life • UL-Listed for Model 330s Benefits • Easy integration with one to three Model 330s or one Capstone 60 • Low inlet gas pressure capability • Once/year low-cost maintenance • Long life, proven reliability • High efficiency • Quiet operation • Very low vibration Capstone Integrated Fuel SystemTM Optional Accessory The Product Fuel System Power Use vs. Pressure & Number of MicroTurbines 6 5 4 3 2 1 Operating Parameters: • Min inlet pressure: 0.5 psig • Max outlet pressure: 100 psig • Max inlet temperature: 120o F • Max outlet temperature: 150o F Inlet Gas Requirements Clean, Dry Pipeline Quality < 45 ppm H2S < 150 ppm H2O < 2.5% CO2 4.4 3 Model 330s 3.3 2.6 2.6 2.5 1 - 2 Model 330s or one Capstone 60 2.4 (not rated for multiple Capstone 60s) 0.5 5 10 15 Inlet Pressure (psig) Note: Requires Capstone M3XEHPFKIT external fuel kit. Performance Specifications Under ISO Conditions (15o C / 59o F @ sea level) • Ambient temp range: 14-120o F* • Oil carry-over: <5 ppm • Vibration: 3 mil @ 60 Hz • Power: 4.5 kW @ 60 Hz Service @ 8,000 hrs • Top up oil level • Clean air intake/exhaust screens • Replace inlet filter • Replace oil separator CAPSTONE TURBINE CORPORATION Dimensions H: 1178 mm / 42” W: 601 mm / 24” L: 1072 mm / 46” Weight 250 kg / 550 lb Typical Sound Level 55 dBA @ 10 m Note: Capstone reserves the right to change or modify without notice the design or equipment specifications without incurring any obligation either with respect to equipment previously sold or in the process of construction. *Heat trace kit required for operation below 14 ̊F. www.microturbine.com For Use With Low-Pressure Natural Gas © 2000 Copyright Capstone Turbine Corp. 11/2000 ss-IFS p/n: 511064-002 KilowattsPDF Image | Capstone Integrated Fuel SystemTM For Use With Low-Pressure Natural Gas

PDF Search Title:

Capstone Integrated Fuel SystemTM For Use With Low-Pressure Natural GasOriginal File Name Searched:

cpst_copeland.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |