PDF Publication Title:

Text from PDF Page: 017

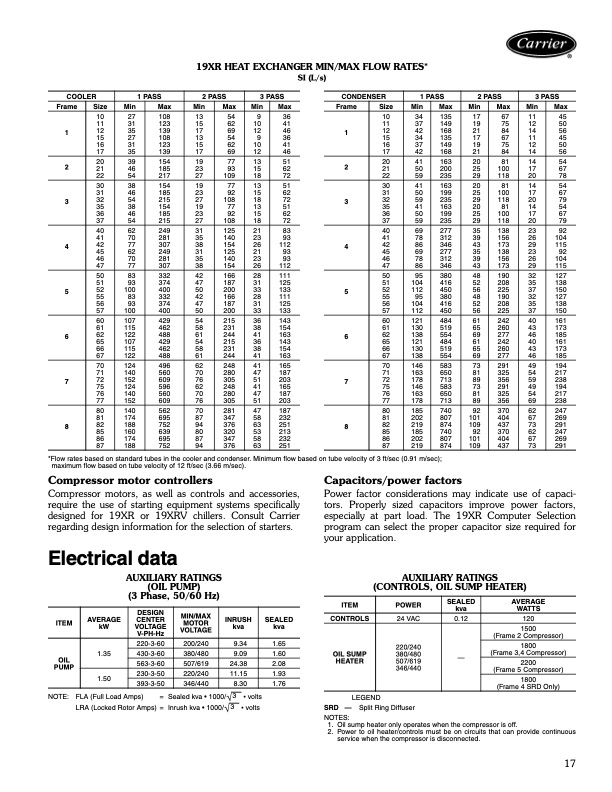

62 72 83 93 4 112 93 93 112 111 125 5 133 111 125 133 143 154 6 163 143 154 163 165 187 7 203 165 187 203 187 232 8 251 213 232 251 4 5 6 7 8 19XR HEAT EXCHANGER MIN/MAX FLOW RATES* SI (L/s) COOLER 3 PASS Frame Max 36 41 CONDENSER Frame 3 PASS Max 45 50 56 45 50 56 54 67 78 54 67 79 54 67 79 92 104 115 92 104 115 127 138 150 127 138 150 161 173 185 161 173 185 194 217 238 194 217 238 247 269 291 247 269 291 Size 10 11 12 15 16 17 20 21 22 30 31 32 35 36 37 40 41 42 45 46 47 50 51 52 55 56 57 60 61 62 65 66 67 70 71 72 75 76 77 80 81 82 85 86 87 Min 27 31 35 27 31 35 39 46 54 38 46 54 38 46 54 62 70 77 62 70 77 83 93 100 83 93 100 107 115 122 107 115 122 124 140 152 124 140 152 140 174 188 160 174 188 1 PASS Max 108 123 139 108 123 139 154 185 217 154 185 215 154 185 215 249 281 307 249 281 307 332 374 400 332 374 400 429 462 488 429 462 488 496 560 609 596 560 609 562 695 752 639 695 752 Min 13 15 17 13 15 17 19 23 27 19 23 27 19 23 27 31 35 38 31 35 38 42 47 50 42 47 50 54 58 61 54 58 61 62 70 76 62 70 76 70 87 94 80 87 94 2 PASS Max 54 62 69 54 62 69 77 93 109 77 92 108 77 92 108 125 140 154 125 140 154 166 187 200 166 187 200 215 231 244 215 231 244 248 280 305 248 280 305 281 347 376 320 347 376 Min 9 10 12 9 10 12 13 15 18 13 15 18 13 15 18 21 23 26 21 23 26 28 31 33 28 31 33 36 38 41 36 38 41 41 47 51 41 47 51 47 58 63 53 58 63 Size 10 11 12 15 16 17 20 21 22 30 31 32 35 36 37 40 41 42 45 46 47 50 51 52 55 56 57 60 61 62 65 66 67 70 71 72 75 76 77 80 81 82 85 86 87 Min 34 37 42 34 37 42 41 50 59 41 50 59 41 50 59 69 78 86 69 78 86 95 104 112 95 104 112 121 130 138 121 130 138 146 163 178 146 163 178 185 202 219 185 202 219 1 PASS Max 135 149 168 135 149 168 163 200 235 163 199 235 163 199 235 277 312 346 277 312 346 380 416 450 380 416 450 484 519 554 484 519 554 583 650 713 583 650 713 740 807 874 740 807 874 Min 17 19 21 17 19 21 20 25 29 20 25 29 20 25 29 35 39 43 35 39 43 48 52 56 48 52 56 61 65 69 61 65 69 73 81 89 73 81 89 92 101 109 92 101 109 2 PASS Max 67 75 84 67 75 84 81 100 118 81 100 118 81 100 118 138 156 173 138 156 173 190 208 225 190 208 225 242 260 277 242 260 277 291 325 356 291 325 356 370 404 437 370 404 437 Min 11 12 14 11 12 14 14 17 20 14 17 20 14 17 20 23 26 29 23 26 29 32 35 37 32 35 37 40 43 46 40 43 46 49 54 59 49 54 69 62 67 73 62 67 73 1 461 36 41 46 51 2 622 72 51 62 3 723 51 *Flow rates based on standard tubes in the cooler and condenser. Minimum flow based on tube velocity of 3 ft/sec (0.91 m/sec); maximum flow based on tube velocity of 12 ft/sec (3.66 m/sec). Compressor motor controllers Compressor motors, as well as controls and accessories, require the use of starting equipment systems specifically designed for 19XR or 19XRV chillers. Consult Carrier regarding design information for the selection of starters. Capacitors/power factors Electrical data AUXILIARY RATINGS (OIL PUMP) (3 Phase, 50/60 Hz) AUXILIARY RATINGS (CONTROLS, OIL SUMP HEATER) Power factor considerations may indicate use of capaci- tors. Properly sized capacitors improve power factors, especially at part load. The 19XR Computer Selection program can select the proper capacitor size required for your application. POWER SEALED kva 24 VAC 0.12 220/240 380/480 507/619 346/440 — AVERAGE kW DESIGN CENTER VOLTAGE V-PH-Hz MIN/MAX MOTOR VOLTAGE INRUSH kva 1.35 220-3-60 200/240 9.34 430-3-60 380/480 9.09 563-3-60 507/619 24.38 1.50 230-3-50 220/240 11.15 393-3-50 346/440 8.30 ITEM OIL PUMP NOTE: SEALED kva 1.65 1.60 2.08 1.93 1.76 ITEM CONTROLS OIL SUMP HEATER AVERAGE WATTS 120 1500 (Frame 2 Compressor) 1800 (Frame 3,4 Compressor) 2200 (Frame 5 Compressor) 1800 (Frame 4 SRD Only) = Sealed kva • 1000/√—3 • volts FLA (Full Load Amps) LRA (Locked Rotor Amps) = Inrush kva • 1000/√—3 • volts SRD LEGEND — Split Ring Diffuser NOTES: 1. Oil sump heater only operates when the compressor is off. 2. Power to oil heater/controls must be on circuits that can provide continuous service when the compressor is disconnected. 17PDF Image | Carrier Product Data 19XR,XRV High-Efficiency Hermetic Centrifugal Liquid Chiller 50/60 Hz HFC-134a 19XR — 200 to 1500 Nominal Tons (703 to 5275 kW) 19XRV — 200 to 800 Nominal Tons (703 to 2813 kW)

PDF Search Title:

Carrier Product Data 19XR,XRV High-Efficiency Hermetic Centrifugal Liquid Chiller 50/60 Hz HFC-134a 19XR — 200 to 1500 Nominal Tons (703 to 5275 kW) 19XRV — 200 to 800 Nominal Tons (703 to 2813 kW)Original File Name Searched:

19XRdata.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |