PDF Publication Title:

Text from PDF Page: 011

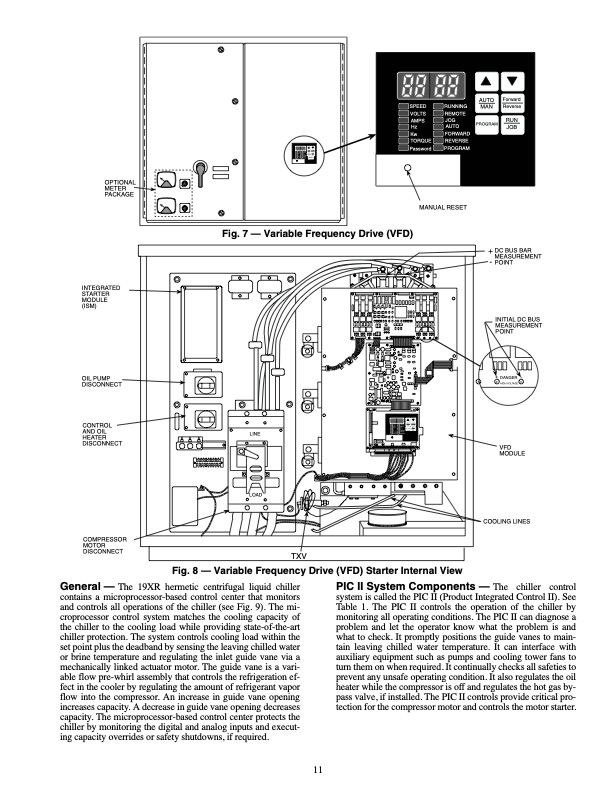

SVPOELETDS AHMz PS KTOwRQUE Password RUENMNOITNEG JAOUGTO FROEVREWRASRED PROGRAM AMUATNO FRoervwearsrde GPRAOM- RJOUBN ENTER SPEED RUNNING VOLTS REMOTE AMPS JOG Hz AUTO Kw FORWARD TORQUE REVERSE Password PROGRAM AUTO MAN PROGRAM Forward Reverse RUN JOB ENTER OPTIONAL METER PACKAGE INTEGRATED STARTER MODULE (ISM) OIL PUMP DISCONNECT CONTROL AND OIL HEATER DISCONNECT COMPRESSOR MOTOR DISCONNECT MANUAL RESET Fig. 7 — Variable Frequency Drive (VFD) SPEED RUNNING VOLTS REMOTE AMPS JOG Hz AUTO Kw FORWARD TORQUE REVERSE Password PROGRAM AMUATNO FRoervwearsrde LINE LOAD PROGRAM RUN JOB ENTER TXV + DC BUS BAR MEASUREMENT - POINT INITIAL DC BUS MEASUREMENT POINT + DANGER - HIGH VOLTAGE VFD MODULE COOLING LINES Fig. 8 — Variable Frequency Drive (VFD) Starter Internal View General — The 19XR hermetic centrifugal liquid chiller contains a microprocessor-based control center that monitors and controls all operations of the chiller (see Fig. 9). The mi- croprocessor control system matches the cooling capacity of the chiller to the cooling load while providing state-of-the-art chiller protection. The system controls cooling load within the set point plus the deadband by sensing the leaving chilled water or brine temperature and regulating the inlet guide vane via a mechanically linked actuator motor. The guide vane is a vari- able flow pre-whirl assembly that controls the refrigeration ef- fect in the cooler by regulating the amount of refrigerant vapor flow into the compressor. An increase in guide vane opening increases capacity. A decrease in guide vane opening decreases capacity. The microprocessor-based control center protects the chiller by monitoring the digital and analog inputs and execut- ing capacity overrides or safety shutdowns, if required. PIC II System Components — The chiller control system is called the PIC II (Product Integrated Control II). See Table 1. The PIC II controls the operation of the chiller by monitoring all operating conditions. The PIC II can diagnose a problem and let the operator know what the problem is and what to check. It promptly positions the guide vanes to main- tain leaving chilled water temperature. It can interface with auxiliary equipment such as pumps and cooling tower fans to turn them on when required. It continually checks all safeties to prevent any unsafe operating condition. It also regulates the oil heater while the compressor is off and regulates the hot gas by- pass valve, if installed. The PIC II controls provide critical pro- tection for the compressor motor and controls the motor starter. 11PDF Image | Carrier 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a Start-Up, Operation, and Maintenance Instructions Safety Considerations

PDF Search Title:

Carrier 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a Start-Up, Operation, and Maintenance Instructions Safety ConsiderationsOriginal File Name Searched:

19xr-4ss_Startup_PICII.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |