PDF Publication Title:

Text from PDF Page: 005

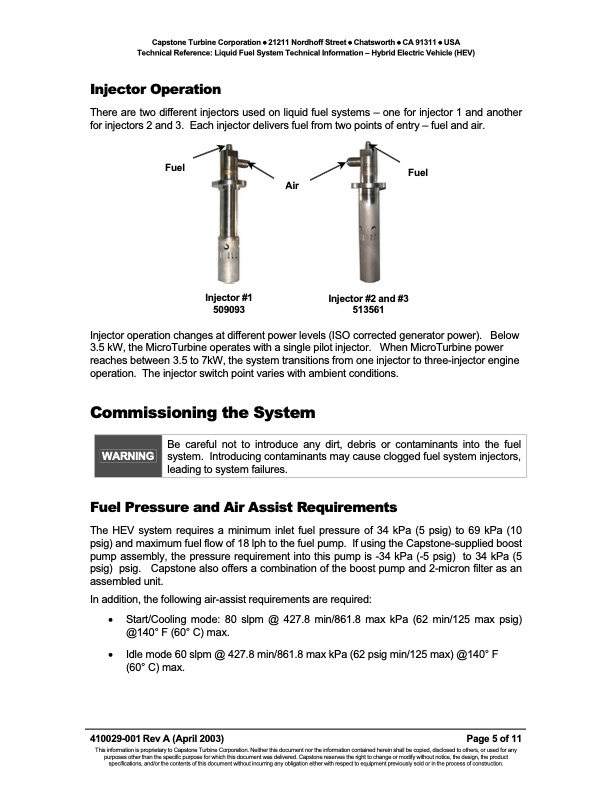

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Technical Reference: Liquid Fuel System Technical Information – Hybrid Electric Vehicle (HEV) Injector Operation There are two different injectors used on liquid fuel systems – one for injector 1 and another for injectors 2 and 3. Each injector delivers fuel from two points of entry – fuel and air. Fuel Fuel Air Injector #1 509093 Injector operation changes at different power levels (ISO corrected generator power). Below 3.5 kW, the MicroTurbine operates with a single pilot injector. When MicroTurbine power reaches between 3.5 to 7kW, the system transitions from one injector to three-injector engine operation. The injector switch point varies with ambient conditions. Commissioning the System Fuel Pressure and Air Assist Requirements The HEV system requires a minimum inlet fuel pressure of 34 kPa (5 psig) to 69 kPa (10 psig) and maximum fuel flow of 18 lph to the fuel pump. If using the Capstone-supplied boost pump assembly, the pressure requirement into this pump is -34 kPa (-5 psig) to 34 kPa (5 psig) psig. Capstone also offers a combination of the boost pump and 2-micron filter as an assembled unit. In addition, the following air-assist requirements are required: • Start/Cooling mode: 80 slpm @ 427.8 min/861.8 max kPa (62 min/125 max psig) @140° F (60° C) max. • Idle mode 60 slpm @ 427.8 min/861.8 max kPa (62 psig min/125 max) @140° F (60° C) max. 410029-001 Rev A (April 2003) Page 5 of 11 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction. Injector #2 and #3 513561 WARNING Be careful not to introduce any dirt, debris or contaminants into the fuel system. Introducing contaminants may cause clogged fuel system injectors, leading to system failures.PDF Image | Technical Reference Liquid Fuel System Technical Information – Hybrid Electric Vehicle (HEV)

PDF Search Title:

Technical Reference Liquid Fuel System Technical Information – Hybrid Electric Vehicle (HEV)Original File Name Searched:

410029_HELOR_Tech_Ref.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |