PDF Publication Title:

Text from PDF Page: 031

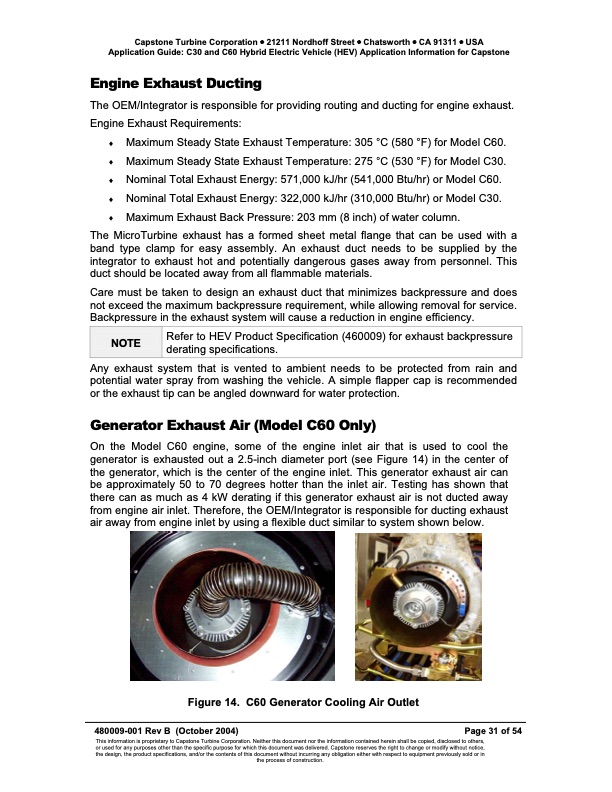

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Application Guide: C30 and C60 Hybrid Electric Vehicle (HEV) Application Information for Capstone Engine Exhaust Ducting The OEM/Integrator is responsible for providing routing and ducting for engine exhaust. Engine Exhaust Requirements: ♦ Maximum Steady State Exhaust Temperature: 305 °C (580 °F) for Model C60. ♦ Maximum Steady State Exhaust Temperature: 275 °C (530 °F) for Model C30. ♦ Nominal Total Exhaust Energy: 571,000 kJ/hr (541,000 Btu/hr) or Model C60. ♦ Nominal Total Exhaust Energy: 322,000 kJ/hr (310,000 Btu/hr) or Model C30. ♦ Maximum Exhaust Back Pressure: 203 mm (8 inch) of water column. The MicroTurbine exhaust has a formed sheet metal flange that can be used with a band type clamp for easy assembly. An exhaust duct needs to be supplied by the integrator to exhaust hot and potentially dangerous gases away from personnel. This duct should be located away from all flammable materials. Care must be taken to design an exhaust duct that minimizes backpressure and does not exceed the maximum backpressure requirement, while allowing removal for service. Backpressure in the exhaust system will cause a reduction in engine efficiency. NOTE Refer to HEV Product Specification (460009) for exhaust backpressure derating specifications. Any exhaust system that is vented to ambient needs to be protected from rain and potential water spray from washing the vehicle. A simple flapper cap is recommended or the exhaust tip can be angled downward for water protection. Generator Exhaust Air (Model C60 Only) On the Model C60 engine, some of the engine inlet air that is used to cool the generator is exhausted out a 2.5-inch diameter port (see Figure 14) in the center of the generator, which is the center of the engine inlet. This generator exhaust air can be approximately 50 to 70 degrees hotter than the inlet air. Testing has shown that there can as much as 4 kW derating if this generator exhaust air is not ducted away from engine air inlet. Therefore, the OEM/Integrator is responsible for ducting exhaust air away from engine inlet by using a flexible duct similar to system shown below. Figure 14. C60 Generator Cooling Air Outlet 480009-001 Rev B (October 2004) Page 31 of 54 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Application Guide Model C30 and C60 HEV Application Information

PDF Search Title:

Application Guide Model C30 and C60 HEV Application InformationOriginal File Name Searched:

480009_HEV_Application_Guide.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |