PDF Publication Title:

Text from PDF Page: 001

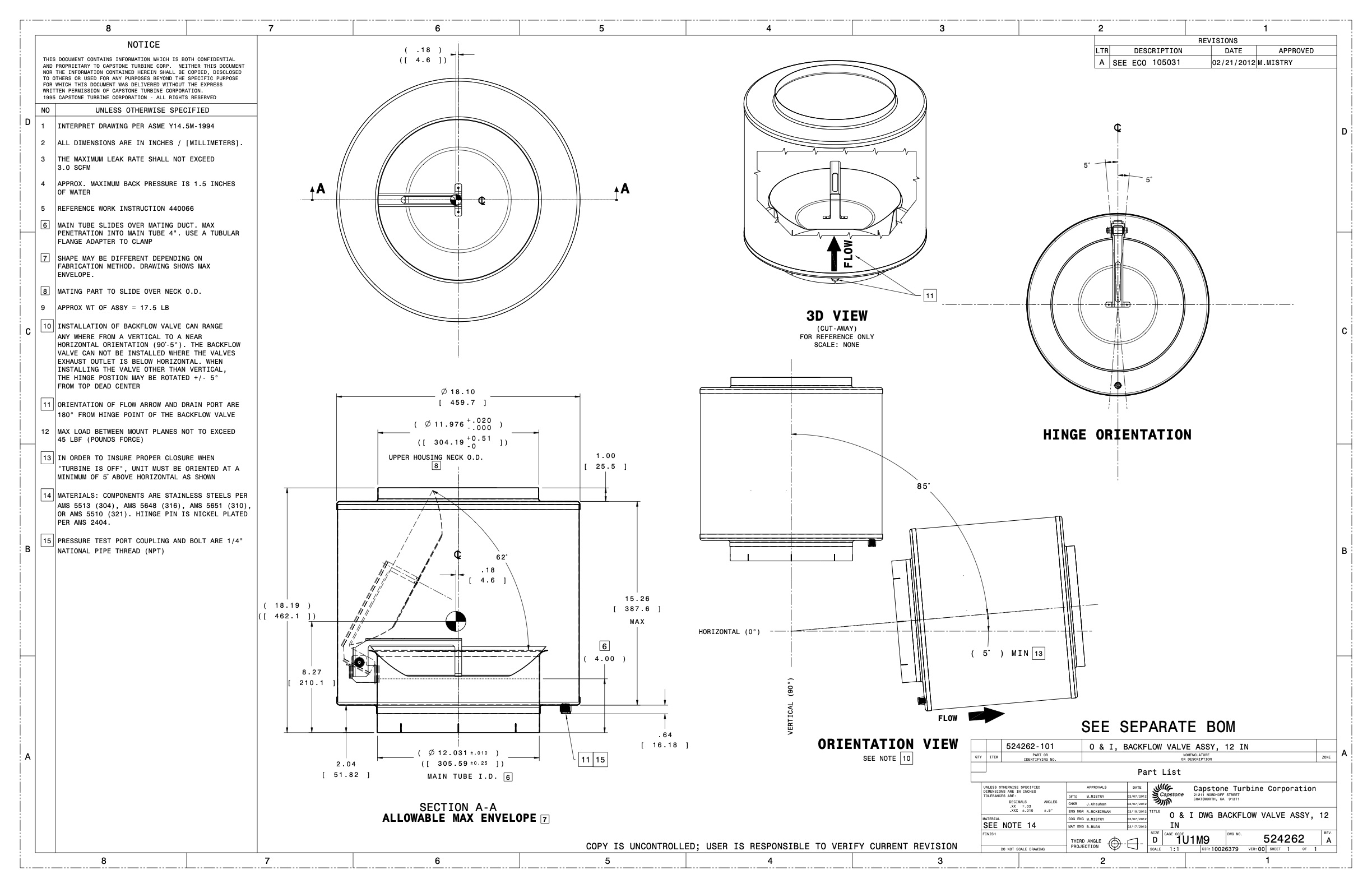

C 3D VIEW (CUT-AWAY) FOR REFERENCE ONLY SCALE: NONE C B 62 [4.6] B 87654321 NOTICE THIS DOCUMENT CONTAINS INFORMATION WHICH IS BOTH CONFIDENTIAL AND PROPRIETARY TO CAPSTONE TURBINE CORP. NEITHER THIS DOCUMENT NOR THE INFORMATION CONTAINED HEREIN SHALL BE COPIED, DISCLOSED TO OTHERS OR USED FOR ANY PURPOSES BEYOND THE SPECIFIC PURPOSE FOR WHICH THIS DOCUMENT WAS DELIVERED WITHOUT THE EXPRESS WRITTEN PERMISSION OF CAPSTONE TURBINE CORPORATION. 1995 CAPSTONE TURBINE CORPORATION - ALL RIGHTS RESERVED NO UNLESS OTHERWISE SPECIFIED D (.18) ([ 4.6 ]) AA LTR DESCRIPTION A SEE ECO 105031 5 REVISIONS DATE APPROVED 02/21/2012 M.MISTRY 1 INTERPRET DRAWING PER ASME Y14.5M-1994 2 ALL DIMENSIONS ARE IN INCHES / [MILLIMETERS]. 3 THE MAXIMUM LEAK RATE SHALL NOT EXCEED 3.0 SCFM 4 APPROX. MAXIMUM BACK PRESSURE IS 1.5 INCHES OF WATER 5 REFERENCE WORK INSTRUCTION 440066 6 MAIN TUBE SLIDES OVER MATING DUCT. MAX PENETRATION INTO MAIN TUBE 4". USE A TUBULAR FLANGE ADAPTER TO CLAMP 7 SHAPE MAY BE DIFFERENT DEPENDING ON FABRICATION METHOD. DRAWING SHOWS MAX ENVELOPE. 8 MATING PART TO SLIDE OVER NECK O.D. 9 APPROX WT OF ASSY = 17.5 LB 10 INSTALLATION OF BACKFLOW VALVE CAN RANGE ANY WHERE FROM A VERTICAL TO A NEAR HORIZONTAL ORIENTATION (90-5°). THE BACKFLOW VALVE CAN NOT BE INSTALLED WHERE THE VALVES EXHAUST OUTLET IS BELOW HORIZONTAL. WHEN INSTALLING THE VALVE OTHER THAN VERTICAL, THE HINGE POSTION MAY BE ROTATED +/- 5° FROM TOP DEAD CENTER 11 ORIENTATION OF FLOW ARROW AND DRAIN PORT ARE 180° FROM HINGE POINT OF THE BACKFLOW VALVE 12 MAX LOAD BETWEEN MOUNT PLANES NOT TO EXCEED 45 LBF (POUNDS FORCE) 13 IN ORDER TO INSURE PROPER CLOSURE WHEN "TURBINE IS OFF", UNIT MUST BE ORIENTED AT A MINIMUM OF 5 ABOVE HORIZONTAL AS SHOWN 14 MATERIALS: COMPONENTS ARE STAINLESS STEELS PER AMS 5513 (304), AMS 5648 (316), AMS 5651 (310), OR AMS 5510 (321). HIINGE PIN IS NICKEL PLATED PER AMS 2404. 15 PRESSURE TEST PORT COUPLING AND BOLT ARE 1/4" NATIONAL PIPE THREAD (NPT) D ( ([ 18.10 [ 459.7 ] 11.976 +.020 ) -.000 304.19 +0.51 ]) -0 HINGE ORIENTATION 1.00 8 [25.5] UPPER HOUSING NECK O.D. 85 11 5 VERTICAL (90°) FLOW A QTY ITEM NOMENCLATURE OR DESCRIPTION ZONE ( 18.19 ) ([ 462.1 ]) 8.27 [ 210.1 ] 2.04 [ 51.82 ] 15.26 [ 387.6 ] MAX ( ([ 12.031 ±.010 ) 305.59 ±0.25 ]) .64 [ 16.18 ] FLOW ORIENTATION VIEW SEE NOTE 10 524262-101 PART OR IDENTIFYING NO. SEE SEPARATE BOM O & I, BACKFLOW VALVE ASSY, 12 IN A MAIN TUBE I.D. SECTION A-A 6 Part List ALLOWABLE MAX ENVELOPE 7 TITLE O & I DWG BACKFLOW VALVE ASSY, 12 IN .18 6 (4.00) 11 15 ( 5 ) MIN 13 COPY IS UNCONTROLLED; USER IS RESPONSIBLE TO VERIFY CURRENT REVISION 87654321 HORIZONTAL (0°) UNLESS OTHERWISE SPECIFIED DIMENSIONS ARE IN INCHES TOLERANCES ARE: DECIMALS .XX ±.03 .XXX ±.010 MATERIAL SEE NOTE 14 FINISH APPROVALS M.MISTRY J.Chauhan ENG MGR R.MCKEIRNAN COG ENG M.MISTRY MAT ENG B.RUAN THIRD ANGLE PROJECTION DATE 02/07/2012 02/07/2012 02/15/2012 02/07/2012 02/17/2012 Capstone Turbine Corporation 21211 NORDHOFF STREET CHATSWORTH, CA 91311 DO NOT SCALE DRAWING ANGLES ±.5° DFTG CHKR SIZE D CAGE CODE DWG NO. 524262 VER:00 SHEET 1 OF REV. A 1 1U1M9 SCALE 1:1 DIR:10026379PDF Image | O&I Backflow Valve Assy 12 Inch Rev

PDF Search Title:

O&I Backflow Valve Assy 12 Inch RevOriginal File Name Searched:

O&I_BACKFLOW_VALVE_ASSY_12_INCH_REV_A.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |