PDF Publication Title:

Text from PDF Page: 010

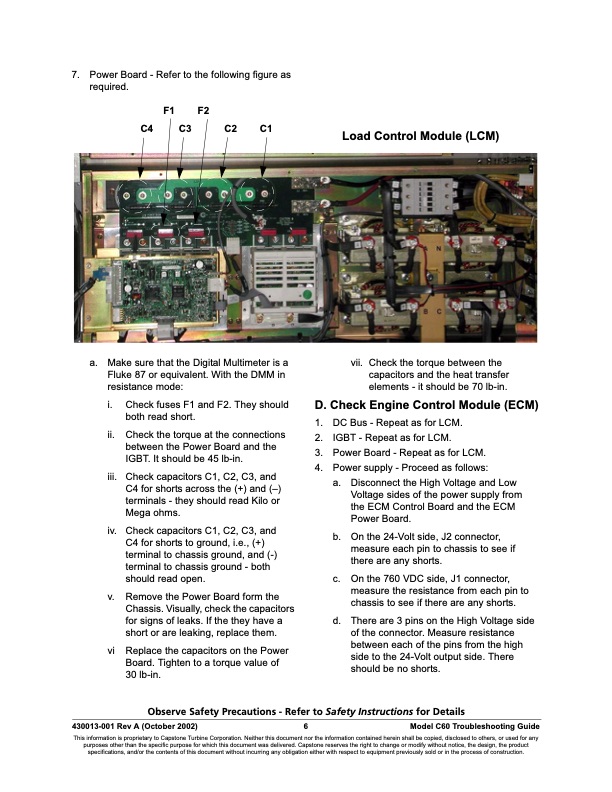

7. Power Board - Refer to the following figure as required. F1 F2 C4 C3 C2 C1 Load Control Module (LCM) a. Make sure that the Digital Multimeter is a Fluke 87 or equivalent. With the DMM in resistance mode: i. Check fuses F1 and F2. They should both read short. ii. Check the torque at the connections between the Power Board and the IGBT. It should be 45 lb-in. iii. Check capacitors C1, C2, C3, and C4 for shorts across the (+) and (–) terminals - they should read Kilo or Mega ohms. iv. Check capacitors C1, C2, C3, and C4 for shorts to ground, i.e., (+) terminal to chassis ground, and (-) terminal to chassis ground - both should read open. v. Remove the Power Board form the Chassis. Visually, check the capacitors for signs of leaks. If the they have a short or are leaking, replace them. vi Replace the capacitors on the Power Board. Tighten to a torque value of 30 lb-in. vii. Check the torque between the capacitors and the heat transfer elements - it should be 70 lb-in. D. Check Engine Control Module (ECM) 1. DC Bus - Repeat as for LCM. 2. IGBT - Repeat as for LCM. 3. Power Board - Repeat as for LCM. 4. Power supply - Proceed as follows: a. Disconnect the High Voltage and Low Voltage sides of the power supply from the ECM Control Board and the ECM Power Board. b. On the 24-Volt side, J2 connector, measure each pin to chassis to see if there are any shorts. c. On the 760 VDC side, J1 connector, measure the resistance from each pin to chassis to see if there are any shorts. d. There are 3 pins on the High Voltage side of the connector. Measure resistance between each of the pins from the high side to the 24-Volt output side. There should be no shorts. Observe Safety Precautions - Refer to Safety Instructions for Details 430013-001 Rev A (October 2002) 6 Model C60 Troubleshooting Guide This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Table of Contents for Series 1000-12000 Fault Codes

PDF Search Title:

Table of Contents for Series 1000-12000 Fault CodesOriginal File Name Searched:

C60FaultCodes.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |