PDF Publication Title:

Text from PDF Page: 015

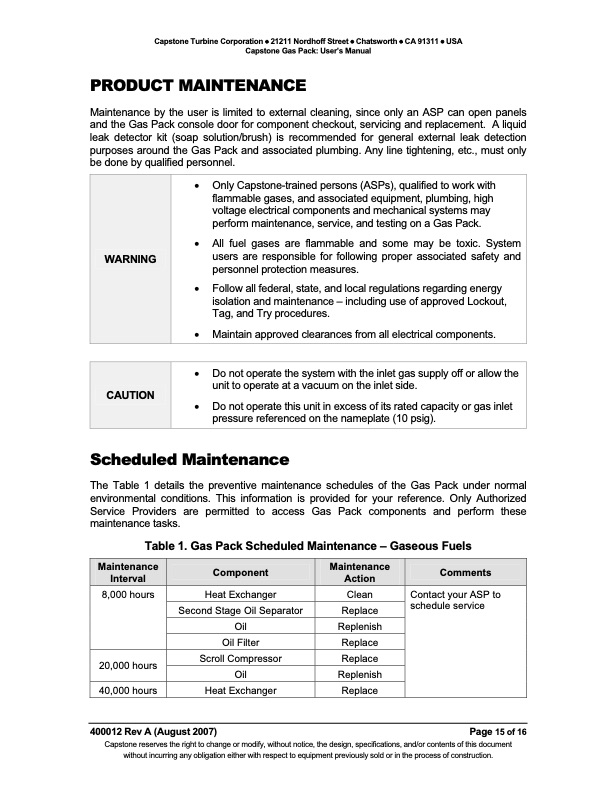

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Capstone Gas Pack: User’s Manual PRODUCT MAINTENANCE Maintenance by the user is limited to external cleaning, since only an ASP can open panels and the Gas Pack console door for component checkout, servicing and replacement. A liquid leak detector kit (soap solution/brush) is recommended for general external leak detection purposes around the Gas Pack and associated plumbing. Any line tightening, etc., must only be done by qualified personnel. WARNING • Only Capstone-trained persons (ASPs), qualified to work with flammable gases, and associated equipment, plumbing, high voltage electrical components and mechanical systems may perform maintenance, service, and testing on a Gas Pack. • All fuel gases are flammable and some may be toxic. System users are responsible for following proper associated safety and personnel protection measures. • Follow all federal, state, and local regulations regarding energy isolation and maintenance – including use of approved Lockout, Tag, and Try procedures. • Maintain approved clearances from all electrical components. CAUTION • Do not operate the system with the inlet gas supply off or allow the unit to operate at a vacuum on the inlet side. • Do not operate this unit in excess of its rated capacity or gas inlet pressure referenced on the nameplate (10 psig). Scheduled Maintenance The Table 1 details the preventive maintenance schedules of the Gas Pack under normal environmental conditions. This information is provided for your reference. Only Authorized Service Providers are permitted to access Gas Pack components and perform these maintenance tasks. Table 1. Gas Pack Scheduled Maintenance – Gaseous Fuels Maintenance Interval Component Maintenance Action Comments 8,000 hours 20,000 hours 40,000 hours Heat Exchanger Second Stage Oil Separator Oil Oil Filter Scroll Compressor Oil Heat Exchanger Clean Replace Replenish Replace Replace Replenish Replace Contact your ASP to schedule service Page 15 of 16 400012 Rev A (August 2007) Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | CAPSTONE GAS PACK USER’S MANUAL

PDF Search Title:

CAPSTONE GAS PACK USER’S MANUALOriginal File Name Searched:

400012A_Gas_Pack_UM.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |