PDF Publication Title:

Text from PDF Page: 042

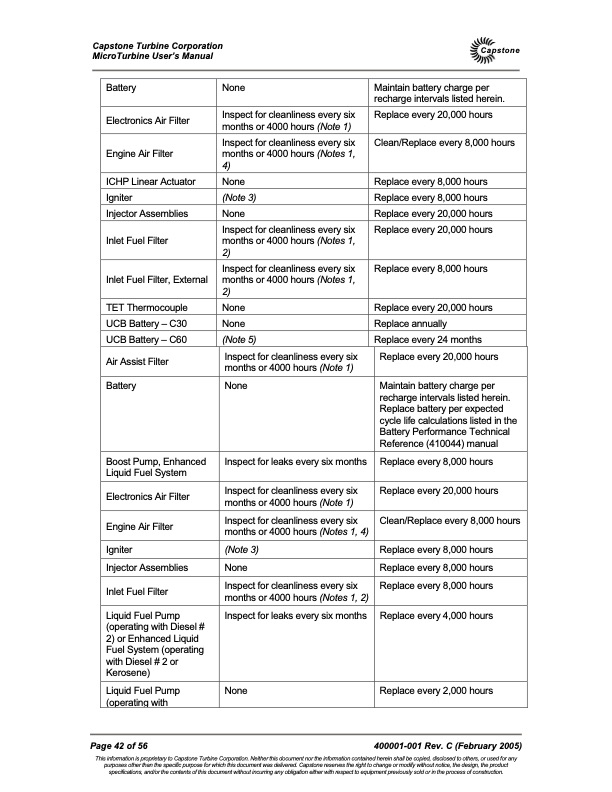

Capstone Turbine Corporation MicroTurbine User’s Manual Capstone Maintain battery charge per recharge intervals listed herein. Replace every 20,000 hours Clean/Replace every 8,000 hours Replace every 8,000 hours Replace every 8,000 hours Replace every 20,000 hours Replace every 20,000 hours Replace every 8,000 hours Replace every 20,000 hours Replace annually Replace every 24 months Replace every 20,000 hours Replace every 8,000 hours Replace every 20,000 hours Clean/Replace every 8,000 hours Replace every 8,000 hours Replace every 8,000 hours Replace every 8,000 hours Replace every 2,000 hours 400001-001 Rev. C (February 2005) Battery Electronics Air Filter Engine Air Filter ICHP Linear Actuator Igniter Injector Assemblies Inlet Fuel Filter Inlet Fuel Filter, External TET Thermocouple UCB Battery – C30 UCB Battery – C60 Air Assist Filter Boost Pump, Enhanced Liquid Fuel System Electronics Air Filter Engine Air Filter Igniter Injector Assemblies Inlet Fuel Filter Liquid Fuel Pump (operating with Page 42 of 56 None Inspect for cleanliness every six months or 4000 hours (Note 1) Inspect for cleanliness every six months or 4000 hours (Notes 1, 4) None (Note 3) None Inspect for cleanliness every six months or 4000 hours (Notes 1, 2) Inspect for cleanliness every six months or 4000 hours (Notes 1, 2) None None (Note 5) Inspect months Inspect Inspect months None Inspect for cleanliness every six months or 4000 hours (Notes 1, 2) None for cleanliness every six or 4000 hours (Note 1) for leaks every six months for cleanliness every six or 4000 hours (Note 1) for cleanliness every six or 4000 hours (Notes 1, 4) (Note 3) Battery None Maintain battery charge per recharge intervals listed herein. Replace battery per expected cycle life calculations listed in the Battery Performance Technical Reference (410044) manual Inspect months Liquid Fuel Pump (operating with Diesel # 2) or Enhanced Liquid Fuel System (operating with Diesel # 2 or Kerosene) Inspect for leaks every six months Replace every 4,000 hours This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | 2002 Capstone User Guide

PDF Search Title:

2002 Capstone User GuideOriginal File Name Searched:

400001C_Users Manual.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |