PDF Publication Title:

Text from PDF Page: 004

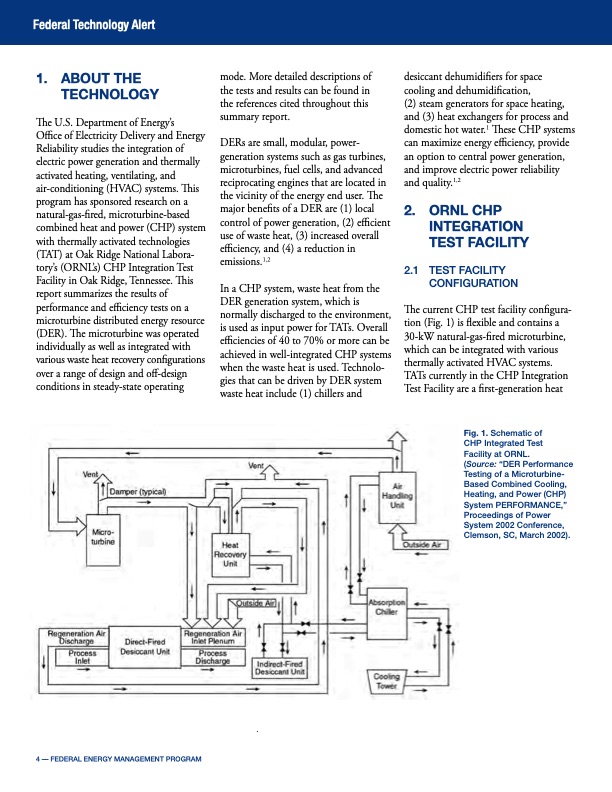

Federal Technology Alert 1. ABOUT THE TECHNOLOGY The U.S. Department of Energy’s Office of Electricity Delivery and Energy Reliability studies the integration of electric power generation and thermally activated heating, ventilating, and air-conditioning (HVAC) systems. This program has sponsored research on a natural-gas-fired, microturbine-based combined heat and power (CHP) system with thermally activated technologies (TAT) at Oak Ridge National Labora tory’s (ORNL’s) CHP Integration Test Facility in Oak Ridge, Tennessee. This report summarizes the results of performance and efficiency tests on a microturbine distributed energy resource (DER). The microturbine was operated individually as well as integrated with various waste heat recovery configurations over a range of design and off-design conditions in steady-state operating mode. More detailed descriptions of the tests and results can be found in the references cited throughout this summary report. DERs are small, modular, power- generation systems such as gas turbines, microturbines, fuel cells, and advanced reciprocating engines that are located in the vicinity of the energy end user. The major benefits of a DER are (1) local control of power generation, (2) efficient use of waste heat, (3) increased overall efficiency, and (4) a reduction in emissions.1,2 In a CHP system, waste heat from the DER generation system, which is normally discharged to the environment, is used as input power for TATs. Overall efficiencies of 40 to 70% or more can be achieved in well-integrated CHP systems when the waste heat is used. Technolo gies that can be driven by DER system waste heat include (1) chillers and desiccant dehumidifiers for space cooling and dehumidification, (2) steam generators for space heating, and (3) heat exchangers for process and domestic hot water.1 These CHP systems can maximize energy efficiency, provide an option to central power generation, and improve electric power reliability and quality.1,2 2. ORNL CHP INTEGRATION TEST FACILITY 2.1 TEST FACILITY CONFIGURATION The current CHP test facility configura tion (Fig. 1) is flexible and contains a 30-kW natural-gas-fired microturbine, which can be integrated with various thermally activated HVAC systems. TATs currently in the CHP Integration Test Facility are a first-generation heat Fig. 1. Schematic of CHP Integrated Test Facility at ORNL. (Source: “DER Performance Testing of a Microturbine- Based Combined Cooling, Heating, and Power (CHP) System PERFORMANCE,” Proceedings of Power System 2002 Conference, Clemson, SC, March 2002). 4 –– FEDERAL ENERGY MANAGEMENT PROGRAM .PDF Image | Summary of Results from Testing a 30-kW-Microturbine and Combined Heat and Power (CHP) System

PDF Search Title:

Summary of Results from Testing a 30-kW-Microturbine and Combined Heat and Power (CHP) SystemOriginal File Name Searched:

fta_microturbinechp.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |