PDF Publication Title:

Text from PDF Page: 032

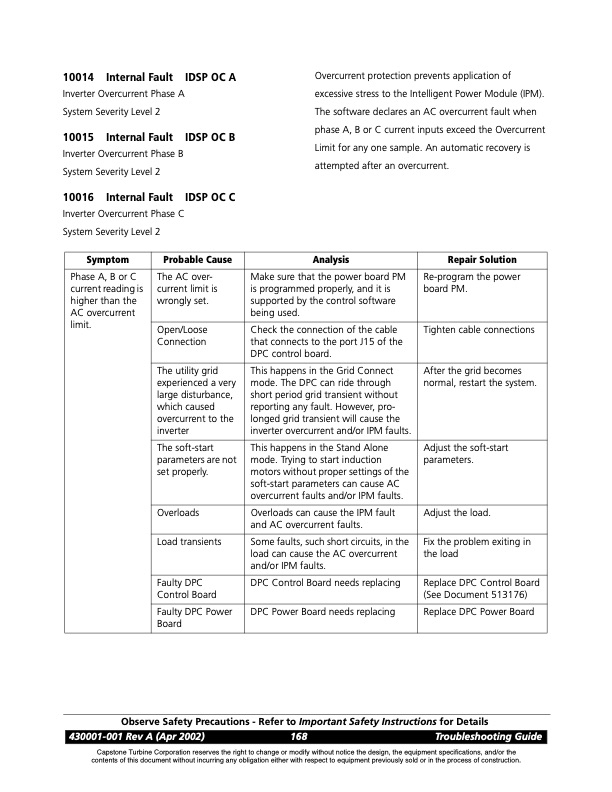

10014 Internal Fault Inverter Overcurrent Phase A System Severity Level 2 10015 Internal Fault Inverter Overcurrent Phase B System Severity Level 2 10016 Internal Fault Inverter Overcurrent Phase C System Severity Level 2 IDSP OC A IDSP OC B IDSP OC C Overcurrent protection prevents application of excessive stress to the Intelligent Power Module (IPM). The software declares an AC overcurrent fault when phase A, B or C current inputs exceed the Overcurrent Limit for any one sample. An automatic recovery is attempted after an overcurrent. Symptom Probable Cause Analysis Repair Solution Phase A, B or C current reading is higher than the AC overcurrent limit. The AC over- current limit is wrongly set. Make sure that the power board PM is programmed properly, and it is supported by the control software being used. Re-program the power board PM. Open/Loose Connection Check the connection of the cable that connects to the port J15 of the DPC control board. Tighten cable connections The utility grid experienced a very large disturbance, which caused overcurrent to the inverter This happens in the Grid Connect mode. The DPC can ride through short period grid transient without reporting any fault. However, pro- longed grid transient will cause the inverter overcurrent and/or IPM faults. After the grid becomes normal, restart the system. The soft-start parameters are not set properly. This happens in the Stand Alone mode. Trying to start induction motors without proper settings of the soft-start parameters can cause AC overcurrent faults and/or IPM faults. Adjust the soft-start parameters. Overloads Overloads can cause the IPM fault and AC overcurrent faults. Adjust the load. Load transients Some faults, such short circuits, in the load can cause the AC overcurrent and/or IPM faults. Fix the problem exiting in the load Faulty DPC Control Board DPC Control Board needs replacing Replace DPC Control Board (See Document 513176) Faulty DPC Power Board DPC Power Board needs replacing Replace DPC Power Board Observe Safety Precautions - Refer to Important Safety Instructions for Details 430001-001 Rev A (Apr 2002) 168 Troubleshooting Guide Capstone Turbine Corporation reserves the right to change or modify without notice the design, the equipment specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Overview SERIES 8000 FAULT CODES Solenoid Faults

PDF Search Title:

Overview SERIES 8000 FAULT CODES Solenoid FaultsOriginal File Name Searched:

C330TroubleBook3Apr02.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |