PDF Publication Title:

Text from PDF Page: 013

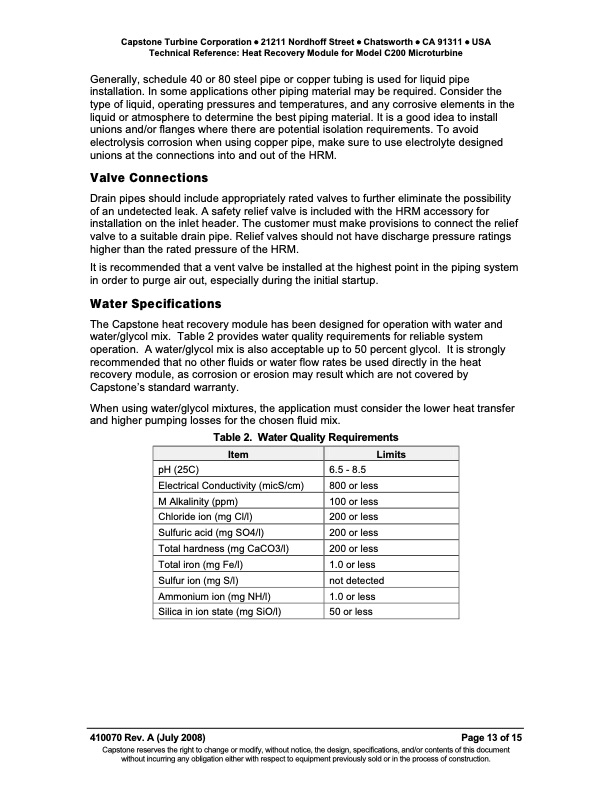

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Technical Reference: Heat Recovery Module for Model C200 Microturbine Generally, schedule 40 or 80 steel pipe or copper tubing is used for liquid pipe installation. In some applications other piping material may be required. Consider the type of liquid, operating pressures and temperatures, and any corrosive elements in the liquid or atmosphere to determine the best piping material. It is a good idea to install unions and/or flanges where there are potential isolation requirements. To avoid electrolysis corrosion when using copper pipe, make sure to use electrolyte designed unions at the connections into and out of the HRM. Valve Connections Drain pipes should include appropriately rated valves to further eliminate the possibility of an undetected leak. A safety relief valve is included with the HRM accessory for installation on the inlet header. The customer must make provisions to connect the relief valve to a suitable drain pipe. Relief valves should not have discharge pressure ratings higher than the rated pressure of the HRM. It is recommended that a vent valve be installed at the highest point in the piping system in order to purge air out, especially during the initial startup. Water Specifications The Capstone heat recovery module has been designed for operation with water and water/glycol mix. Table 2 provides water quality requirements for reliable system operation. A water/glycol mix is also acceptable up to 50 percent glycol. It is strongly recommended that no other fluids or water flow rates be used directly in the heat recovery module, as corrosion or erosion may result which are not covered by Capstone’s standard warranty. When using water/glycol mixtures, the application must consider the lower heat transfer and higher pumping losses for the chosen fluid mix. pH (25C) Electrical Conductivity (micS/cm) M Alkalinity (ppm) Chloride ion (mg Cl/l) Sulfuric acid (mg SO4/l) Total hardness (mg CaCO3/l) Total iron (mg Fe/l) Sulfur ion (mg S/l) Ammonium ion (mg NH/l) Silica in ion state (mg SiO/l) 410070 Rev. A (July 2008) 6.5 - 8.5 800 or less 100 or less 200 or less 200 or less 200 or less 1.0 or less not detected 1.0 or less 50 or less Table 2. Water Quality Requirements Item Limits Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction. Page 13 of 15PDF Image | Technical Reference Model C200 Heat Recovery Module

PDF Search Title:

Technical Reference Model C200 Heat Recovery ModuleOriginal File Name Searched:

410070A_C200_HRM_TR.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |