PDF Publication Title:

Text from PDF Page: 008

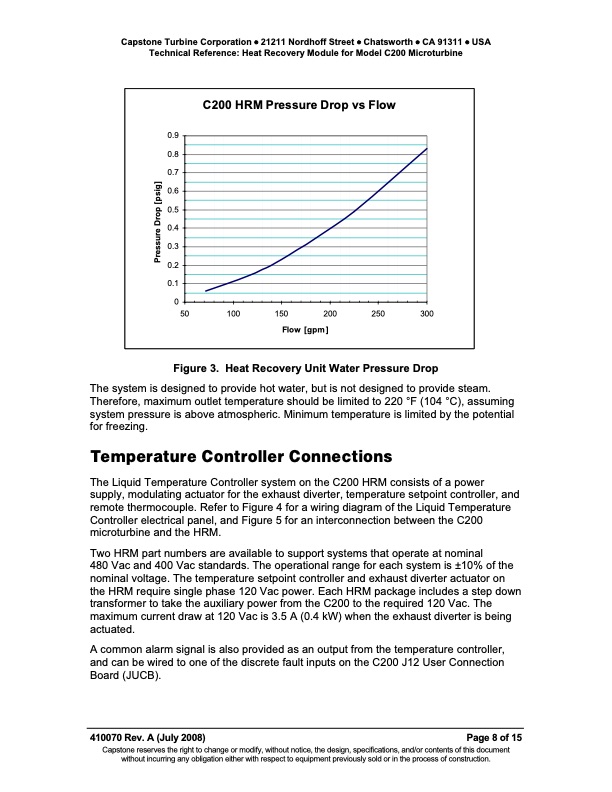

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Technical Reference: Heat Recovery Module for Model C200 Microturbine 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 C200 HRM Pressure Drop vs Flow 50 100 150 200 Flow [gpm] 250 300 Figure 3. Heat Recovery Unit Water Pressure Drop The system is designed to provide hot water, but is not designed to provide steam. Therefore, maximum outlet temperature should be limited to 220 °F (104 °C), assuming system pressure is above atmospheric. Minimum temperature is limited by the potential for freezing. Temperature Controller Connections The Liquid Temperature Controller system on the C200 HRM consists of a power supply, modulating actuator for the exhaust diverter, temperature setpoint controller, and remote thermocouple. Refer to Figure 4 for a wiring diagram of the Liquid Temperature Controller electrical panel, and Figure 5 for an interconnection between the C200 microturbine and the HRM. Two HRM part numbers are available to support systems that operate at nominal 480 Vac and 400 Vac standards. The operational range for each system is ±10% of the nominal voltage. The temperature setpoint controller and exhaust diverter actuator on the HRM require single phase 120 Vac power. Each HRM package includes a step down transformer to take the auxiliary power from the C200 to the required 120 Vac. The maximum current draw at 120 Vac is 3.5 A (0.4 kW) when the exhaust diverter is being actuated. A common alarm signal is also provided as an output from the temperature controller, and can be wired to one of the discrete fault inputs on the C200 J12 User Connection Board (JUCB). 410070 Rev. A (July 2008) Page 8 of 15 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction. Pressure Drop [psig]PDF Image | Technical Reference Model C200 Heat Recovery Module

PDF Search Title:

Technical Reference Model C200 Heat Recovery ModuleOriginal File Name Searched:

410070A_C200_HRM_TR.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |