PDF Publication Title:

Text from PDF Page: 003

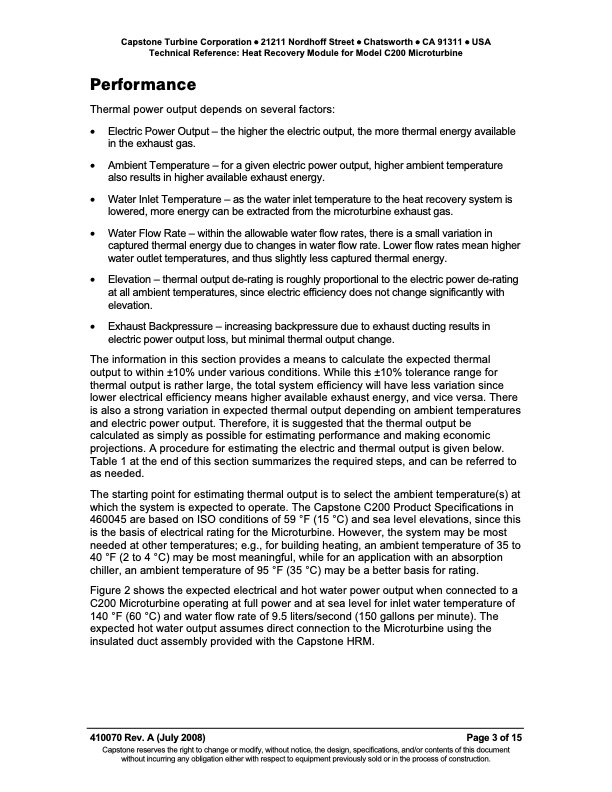

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Technical Reference: Heat Recovery Module for Model C200 Microturbine Performance Thermal power output depends on several factors: • Electric Power Output – the higher the electric output, the more thermal energy available in the exhaust gas. • Ambient Temperature – for a given electric power output, higher ambient temperature also results in higher available exhaust energy. • Water Inlet Temperature – as the water inlet temperature to the heat recovery system is lowered, more energy can be extracted from the microturbine exhaust gas. • Water Flow Rate – within the allowable water flow rates, there is a small variation in captured thermal energy due to changes in water flow rate. Lower flow rates mean higher water outlet temperatures, and thus slightly less captured thermal energy. • Elevation – thermal output de-rating is roughly proportional to the electric power de-rating at all ambient temperatures, since electric efficiency does not change significantly with elevation. • Exhaust Backpressure – increasing backpressure due to exhaust ducting results in electric power output loss, but minimal thermal output change. The information in this section provides a means to calculate the expected thermal output to within ±10% under various conditions. While this ±10% tolerance range for thermal output is rather large, the total system efficiency will have less variation since lower electrical efficiency means higher available exhaust energy, and vice versa. There is also a strong variation in expected thermal output depending on ambient temperatures and electric power output. Therefore, it is suggested that the thermal output be calculated as simply as possible for estimating performance and making economic projections. A procedure for estimating the electric and thermal output is given below. Table 1 at the end of this section summarizes the required steps, and can be referred to as needed. The starting point for estimating thermal output is to select the ambient temperature(s) at which the system is expected to operate. The Capstone C200 Product Specifications in 460045 are based on ISO conditions of 59 °F (15 °C) and sea level elevations, since this is the basis of electrical rating for the Microturbine. However, the system may be most needed at other temperatures; e.g., for building heating, an ambient temperature of 35 to 40 °F (2 to 4 °C) may be most meaningful, while for an application with an absorption chiller, an ambient temperature of 95 °F (35 °C) may be a better basis for rating. Figure 2 shows the expected electrical and hot water power output when connected to a C200 Microturbine operating at full power and at sea level for inlet water temperature of 140 °F (60 °C) and water flow rate of 9.5 liters/second (150 gallons per minute). The expected hot water output assumes direct connection to the Microturbine using the insulated duct assembly provided with the Capstone HRM. 410070 Rev. A (July 2008) Page 3 of 15 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Technical Reference Model C200 Heat Recovery Module

PDF Search Title:

Technical Reference Model C200 Heat Recovery ModuleOriginal File Name Searched:

410070A_C200_HRM_TR.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |