PDF Publication Title:

Text from PDF Page: 052

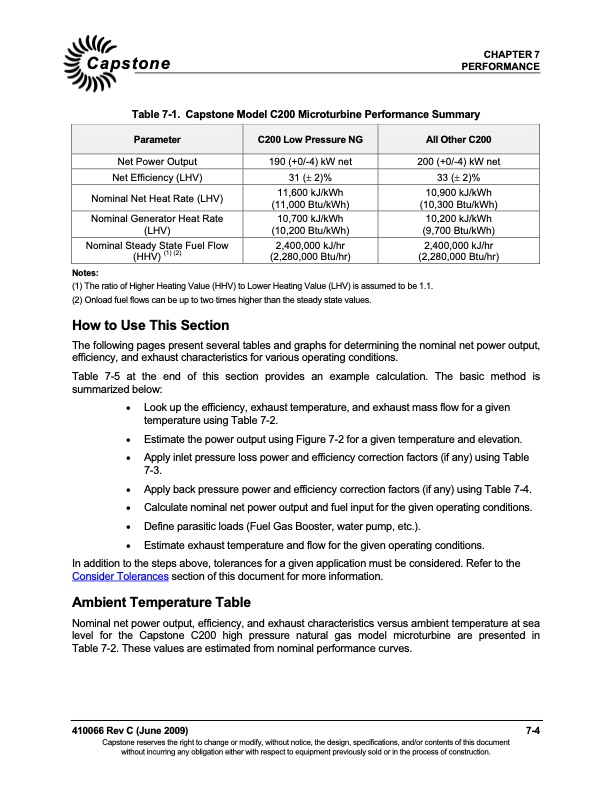

CHAPTER 7 Capstone PERFORMANCE Table 7-1. Capstone Model C200 Microturbine Performance Summary Parameter C200 Low Pressure NG All Other C200 Net Power Output Net Efficiency (LHV) Nominal Net Heat Rate (LHV) Nominal Generator Heat Rate (LHV) Nominal Steady State Fuel Flow (HHV) (1) (2) Notes: 190 (+0/-4) kW net 31 (� 2)% 11,600 kJ/kWh (11,000 Btu/kWh) 10,700 kJ/kWh (10,200 Btu/kWh) 2,400,000 kJ/hr (2,280,000 Btu/hr) 200 (+0/-4) kW net 33 (� 2)% 10,900 kJ/kWh (10,300 Btu/kWh) 10,200 kJ/kWh (9,700 Btu/kWh) 2,400,000 kJ/hr (2,280,000 Btu/hr) (1) The ratio of Higher Heating Value (HHV) to Lower Heating Value (LHV) is assumed to be 1.1. (2) Onload fuel flows can be up to two times higher than the steady state values. How to Use This Section The following pages present several tables and graphs for determining the nominal net power output, efficiency, and exhaust characteristics for various operating conditions. Table 7-5 at the end of this section provides an example calculation. The basic method is summarized below: � Look up the efficiency, exhaust temperature, and exhaust mass flow for a given temperature using Table 7-2. � Estimate the power output using Figure 7-2 for a given temperature and elevation. � Apply inlet pressure loss power and efficiency correction factors (if any) using Table 7-3. � Apply back pressure power and efficiency correction factors (if any) using Table 7-4. � Calculate nominal net power output and fuel input for the given operating conditions. � Define parasitic loads (Fuel Gas Booster, water pump, etc.). � Estimate exhaust temperature and flow for the given operating conditions. In addition to the steps above, tolerances for a given application must be considered. Refer to the Consider Tolerances section of this document for more information. Ambient Temperature Table Nominal net power output, efficiency, and exhaust characteristics versus ambient temperature at sea level for the Capstone C200 high pressure natural gas model microturbine are presented in Table 7-2. These values are estimated from nominal performance curves. 410066 Rev C (June 2009) 7-4 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | CAPSTONE C200 MICROTURBINE TECHNICAL REFERENCE

PDF Search Title:

CAPSTONE C200 MICROTURBINE TECHNICAL REFERENCEOriginal File Name Searched:

410066C_C200_Tech_Ref.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |