PDF Publication Title:

Text from PDF Page: 002

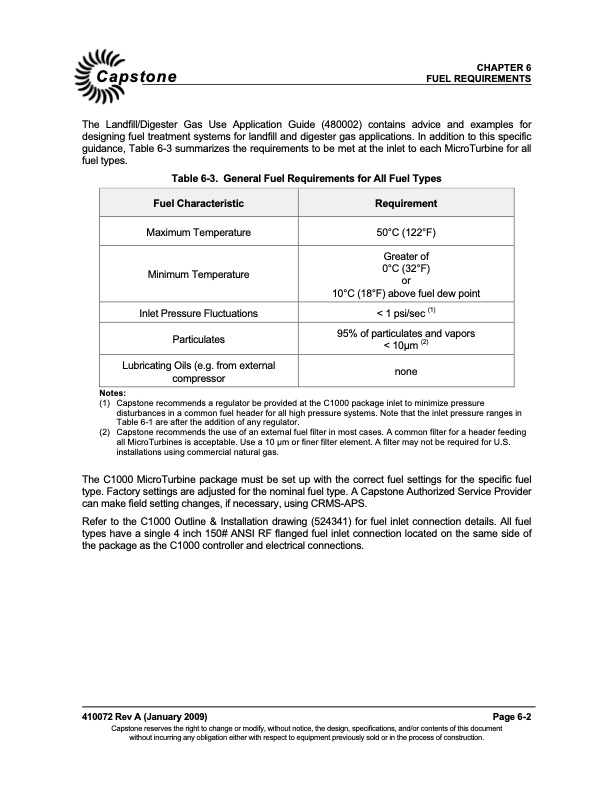

CHAPTER 6 Capstone FUEL REQUIREMENTS The Landfill/Digester Gas Use Application Guide (480002) contains advice and examples for designing fuel treatment systems for landfill and digester gas applications. In addition to this specific guidance, Table 6-3 summarizes the requirements to be met at the inlet to each MicroTurbine for all fuel types. Table 6-3. General Fuel Requirements for All Fuel Types Fuel Characteristic Requirement Maximum Temperature Inlet Pressure Fluctuations Particulates Lubricating Oils (e.g. from external compressor Notes: 50°C (122°F) < 1 psi/sec (1) 95% of particulates and vapors < 10μm (2) none Minimum Temperature Greater of 0°C (32°F) or 10°C (18°F) above fuel dew point (1) Capstone recommends a regulator be provided at the C1000 package inlet to minimize pressure disturbances in a common fuel header for all high pressure systems. Note that the inlet pressure ranges in Table 6-1 are after the addition of any regulator. (2) Capstone recommends the use of an external fuel filter in most cases. A common filter for a header feeding all MicroTurbines is acceptable. Use a 10 μm or finer filter element. A filter may not be required for U.S. installations using commercial natural gas. The C1000 MicroTurbine package must be set up with the correct fuel settings for the specific fuel type. Factory settings are adjusted for the nominal fuel type. A Capstone Authorized Service Provider can make field setting changes, if necessary, using CRMS-APS. Refer to the C1000 Outline & Installation drawing (524341) for fuel inlet connection details. All fuel types have a single 4 inch 150# ANSI RF flanged fuel inlet connection located on the same side of the package as the C1000 controller and electrical connections. 410072 Rev A (January 2009) Page 6-2 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | CHAPTER 6 Capstone FUEL REQUIREMENTS

PDF Search Title:

CHAPTER 6 Capstone FUEL REQUIREMENTSOriginal File Name Searched:

C1000FuelRequirements.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |