PDF Publication Title:

Text from PDF Page: 010

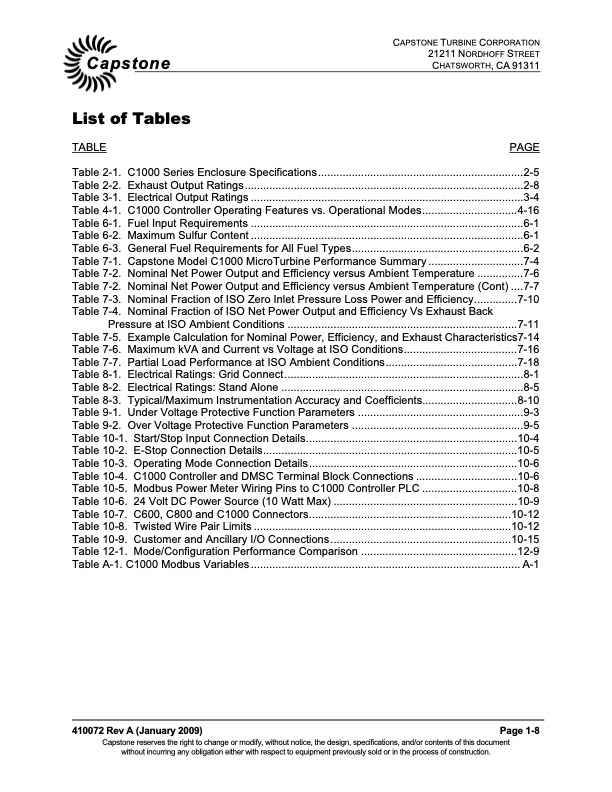

CAPSTONE TURBINE CORPORATION 21211 NORDHOFF STREET Capstone CHATSWORTH, CA 91311 List of Tables TABLE PAGE Table 2-1. C1000 Series Enclosure Specifications...................................................................2-5 Table 2-2. Exhaust Output Ratings...........................................................................................2-8 Table 3-1. Electrical Output Ratings .........................................................................................3-4 Table 4-1. C1000 Controller Operating Features vs. Operational Modes...............................4-16 Table 6-1. Fuel Input Requirements .........................................................................................6-1 Table 6-2. Maximum Sulfur Content .........................................................................................6-1 Table 6-3. General Fuel Requirements for All Fuel Types........................................................6-2 Table 7-1. Capstone Model C1000 MicroTurbine Performance Summary ...............................7-4 Table 7-2. Nominal Net Power Output and Efficiency versus Ambient Temperature ...............7-6 Table 7-2. Nominal Net Power Output and Efficiency versus Ambient Temperature (Cont) ....7-7 Table 7-3. Nominal Fraction of ISO Zero Inlet Pressure Loss Power and Efficiency..............7-10 Table 7-4. Nominal Fraction of ISO Net Power Output and Efficiency Vs Exhaust Back Pressure at ISO Ambient Conditions ...........................................................................7-11 Table 7-5. Example Calculation for Nominal Power, Efficiency, and Exhaust Characteristics7-14 Table 7-6. Maximum kVA and Current vs Voltage at ISO Conditions.....................................7-16 Table 7-7. Partial Load Performance at ISO Ambient Conditions...........................................7-18 Table 8-1. Electrical Ratings: Grid Connect..............................................................................8-1 Table 8-2. Electrical Ratings: Stand Alone ...............................................................................8-5 Table 8-3. Typical/Maximum Instrumentation Accuracy and Coefficients...............................8-10 Table 9-1. Under Voltage Protective Function Parameters ......................................................9-3 Table 9-2. Over Voltage Protective Function Parameters ........................................................9-5 Table 10-1. Start/Stop Input Connection Details.....................................................................10-4 Table 10-2. E-Stop Connection Details...................................................................................10-5 Table 10-3. Operating Mode Connection Details....................................................................10-6 Table 10-4. C1000 Controller and DMSC Terminal Block Connections .................................10-6 Table 10-5. Modbus Power Meter Wiring Pins to C1000 Controller PLC ...............................10-8 Table 10-6. 24 Volt DC Power Source (10 Watt Max) ............................................................10-9 Table 10-7. C600, C800 and C1000 Connectors..................................................................10-12 Table 10-8. Twisted Wire Pair Limits ....................................................................................10-12 Table 10-9. Customer and Ancillary I/O Connections...........................................................10-15 Table 12-1. Mode/Configuration Performance Comparison ...................................................12-9 Table A-1. C1000 Modbus Variables ........................................................................................ A-1 410072 Rev A (January 2009) Page 1-8 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | CAPSTONE C1000 MICROTURBINE SYSTEMS TECHNICAL REFERENCE

PDF Search Title:

CAPSTONE C1000 MICROTURBINE SYSTEMS TECHNICAL REFERENCEOriginal File Name Searched:

410072A_C1000_TR.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |