PDF Publication Title:

Text from PDF Page: 004

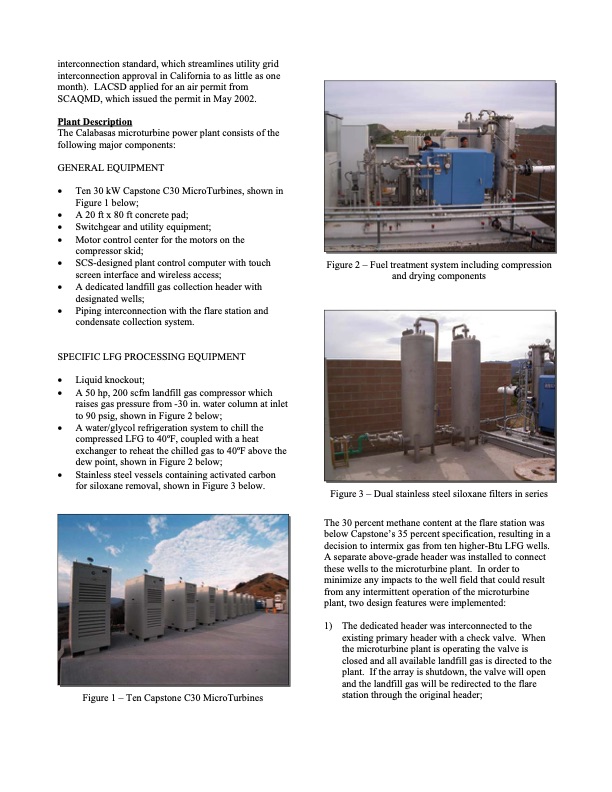

interconnection standard, which streamlines utility grid interconnection approval in California to as little as one month). LACSD applied for an air permit from SCAQMD, which issued the permit in May 2002. Plant Description The Calabasas microturbine power plant consists of the following major components: GENERAL EQUIPMENT • Ten 30 kW Capstone C30 MicroTurbines, shown in Figure 1 below; • A 20 ft x 80 ft concrete pad; • Switchgear and utility equipment; • Motor control center for the motors on the compressor skid; • SCS-designed plant control computer with touch screen interface and wireless access; • A dedicated landfill gas collection header with designated wells; • Piping interconnection with the flare station and condensate collection system. SPECIFIC LFG PROCESSING EQUIPMENT • Liquid knockout; • A 50 hp, 200 scfm landfill gas compressor which raises gas pressure from -30 in. water column at inlet to 90 psig, shown in Figure 2 below; • A water/glycol refrigeration system to chill the compressed LFG to 40oF, coupled with a heat exchanger to reheat the chilled gas to 40oF above the dew point, shown in Figure 2 below; • Stainless steel vessels containing activated carbon for siloxane removal, shown in Figure 3 below. Figure 1 – Ten Capstone C30 MicroTurbines Figure 2 – Fuel treatment system including compression and drying components Figure 3 – Dual stainless steel siloxane filters in series The 30 percent methane content at the flare station was below Capstone’s 35 percent specification, resulting in a decision to intermix gas from ten higher-Btu LFG wells. A separate above-grade header was installed to connect these wells to the microturbine plant. In order to minimize any impacts to the well field that could result from any intermittent operation of the microturbine plant, two design features were implemented: 1) The dedicated header was interconnected to the existing primary header with a check valve. When the microturbine plant is operating the valve is closed and all available landfill gas is directed to the plant. If the array is shutdown, the valve will open and the landfill gas will be redirected to the flare station through the original header;PDF Image | MICROTURBINE OPERATING EXPERIENCE AT LANDFILLS

PDF Search Title:

MICROTURBINE OPERATING EXPERIENCE AT LANDFILLSOriginal File Name Searched:

Benson_Microturbine_Operating_Experience.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |