PDF Publication Title:

Text from PDF Page: 074

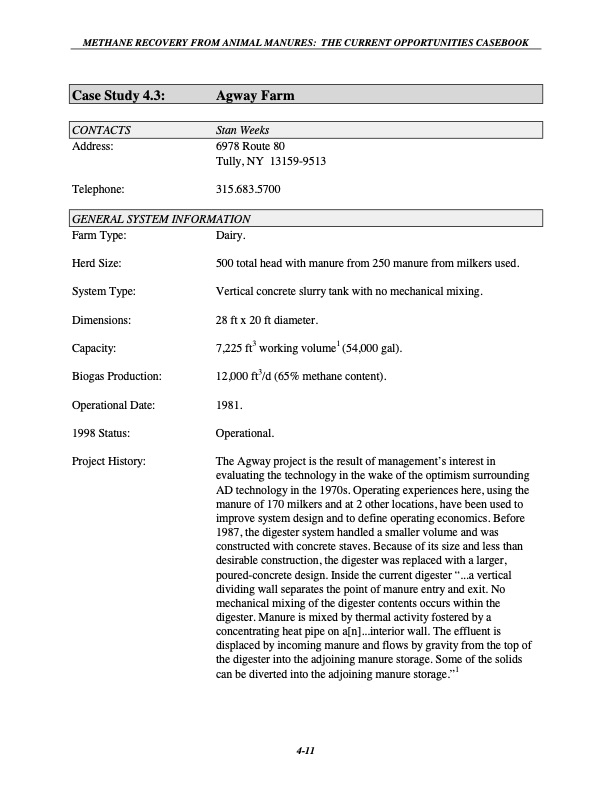

METHANE RECOVERY FROM ANIMAL MANURES: THE CURRENT OPPORTUNITIES CASEBOOK Case Study 4.3: CONTACTS Address: Telephone: Agway Farm Stan Weeks 6978 Route 80 Tully, NY 13159-9513 315.683.5700 GENERAL SYSTEM INFORMATION Farm Type: Herd Size: System Type: Dimensions: Capacity: Biogas Production: Operational Date: 1998 Status: Project History: Dairy. 500 total head with manure from 250 manure from milkers used. Vertical concrete slurry tank with no mechanical mixing. 28 ft x 20 ft diameter. 31 7,225 ft working volume (54,000 gal). 3 12,000 ft /d (65% methane content). 1981. Operational. The Agway project is the result of management’s interest in evaluating the technology in the wake of the optimism surrounding AD technology in the 1970s. Operating experiences here, using the manure of 170 milkers and at 2 other locations, have been used to improve system design and to define operating economics. Before 1987, the digester system handled a smaller volume and was constructed with concrete staves. Because of its size and less than desirable construction, the digester was replaced with a larger, poured-concrete design. Inside the current digester “...a vertical dividing wall separates the point of manure entry and exit. No mechanical mixing of the digester contents occurs within the digester. Manure is mixed by thermal activity fostered by a concentrating heat pipe on a[n]...interior wall. The effluent is displaced by incoming manure and flows by gravity from the top of the digester into the adjoining manure storage. Some of the solids 1 can be diverted into the adjoining manure storage.” 4-11PDF Image | Methane Recovery from Animal Manures The Current Opportunities Casebook

PDF Search Title:

Methane Recovery from Animal Manures The Current Opportunities CasebookOriginal File Name Searched:

biogas02.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |