PDF Publication Title:

Text from PDF Page: 071

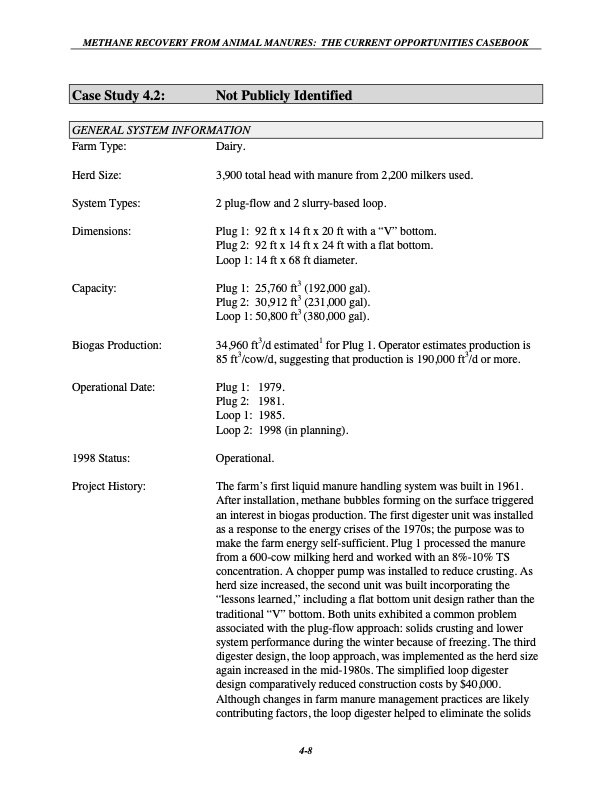

METHANE RECOVERY FROM ANIMAL MANURES: THE CURRENT OPPORTUNITIES CASEBOOK Case Study 4.2: Not Publicly Identified GENERAL SYSTEM INFORMATION Farm Type: Herd Size: System Types: Dimensions: Capacity: BiogasProduction: Operational Date: 1998 Status: Project History: Dairy. 3,900 total head with manure from 2,200 milkers used. 2 plug-flow and 2 slurry-based loop. Plug 1: 92 ft x 14 ft x 20 ft with a “V” bottom. Plug2: 92ftx14ftx24ftwithaflatbottom. Loop 1: 14 ft x 68 ft diameter. 3 Plug 1: 25,760 ft (192,000 gal). 3 Plug 2: 30,912 ft (231,000 gal). 3 Loop 1: 50,800 ft (380,000 gal). 31 34,960ft/destimated forPlug1.Operatorestimatesproductionis 33 85 ft /cow/d, suggesting that production is 190,000 ft /d or more. Plug 1: Plug 2: Loop 1: Loop 2: 1979. 1981. 1985. 1998 (in planning). Operational. The farm’s first liquid manure handling system was built in 1961. After installation, methane bubbles forming on the surface triggered an interest in biogas production. The first digester unit was installed as a response to the energy crises of the 1970s; the purpose was to make the farm energy self-sufficient. Plug 1 processed the manure from a 600-cow milking herd and worked with an 8%-10% TS concentration. A chopper pump was installed to reduce crusting. As herd size increased, the second unit was built incorporating the “lessons learned,” including a flat bottom unit design rather than the traditional “V” bottom. Both units exhibited a common problem associated with the plug-flow approach: solids crusting and lower system performance during the winter because of freezing. The third digester design, the loop approach, was implemented as the herd size again increased in the mid-1980s. The simplified loop digester design comparatively reduced construction costs by $40,000. Although changes in farm manure management practices are likely contributing factors, the loop digester helped to eliminate the solids 4-8PDF Image | Methane Recovery from Animal Manures The Current Opportunities Casebook

PDF Search Title:

Methane Recovery from Animal Manures The Current Opportunities CasebookOriginal File Name Searched:

biogas02.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |