PDF Publication Title:

Text from PDF Page: 068

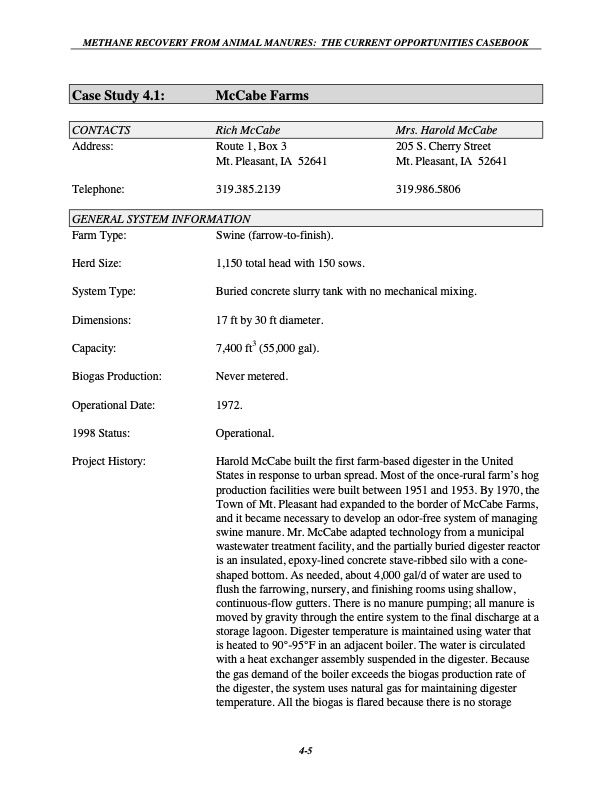

METHANE RECOVERY FROM ANIMAL MANURES: THE CURRENT OPPORTUNITIES CASEBOOK Case Study 4.1: CONTACTS Address: Telephone: McCabe Farms Rich McCabe Route 1, Box 3 Mt. Pleasant, IA 52641 319.385.2139 Mrs. Harold McCabe 205 S. Cherry Street Mt. Pleasant, IA 52641 319.986.5806 GENERAL SYSTEM INFORMATION Farm Type: Herd Size: System Type: Dimensions: Capacity: Biogas Production: Operational Date: 1998 Status: Project History: Swine (farrow-to-finish). 1,150 total head with 150 sows. Buried concrete slurry tank with no mechanical mixing. 17 ft by 30 ft diameter. 3 7,400ft (55,000gal). Never metered. 1972. Operational. Harold McCabe built the first farm-based digester in the United States in response to urban spread. Most of the once-rural farm’s hog production facilities were built between 1951 and 1953. By 1970, the Town of Mt. Pleasant had expanded to the border of McCabe Farms, and it became necessary to develop an odor-free system of managing swine manure. Mr. McCabe adapted technology from a municipal wastewater treatment facility, and the partially buried digester reactor is an insulated, epoxy-lined concrete stave-ribbed silo with a cone- shaped bottom. As needed, about 4,000 gal/d of water are used to flush the farrowing, nursery, and finishing rooms using shallow, continuous-flow gutters. There is no manure pumping; all manure is moved by gravity through the entire system to the final discharge at a storage lagoon. Digester temperature is maintained using water that is heated to 90°-95°F in an adjacent boiler. The water is circulated with a heat exchanger assembly suspended in the digester. Because the gas demand of the boiler exceeds the biogas production rate of the digester, the system uses natural gas for maintaining digester temperature. All the biogas is flared because there is no storage 4-5PDF Image | Methane Recovery from Animal Manures The Current Opportunities Casebook

PDF Search Title:

Methane Recovery from Animal Manures The Current Opportunities CasebookOriginal File Name Searched:

biogas02.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |