PDF Publication Title:

Text from PDF Page: 048

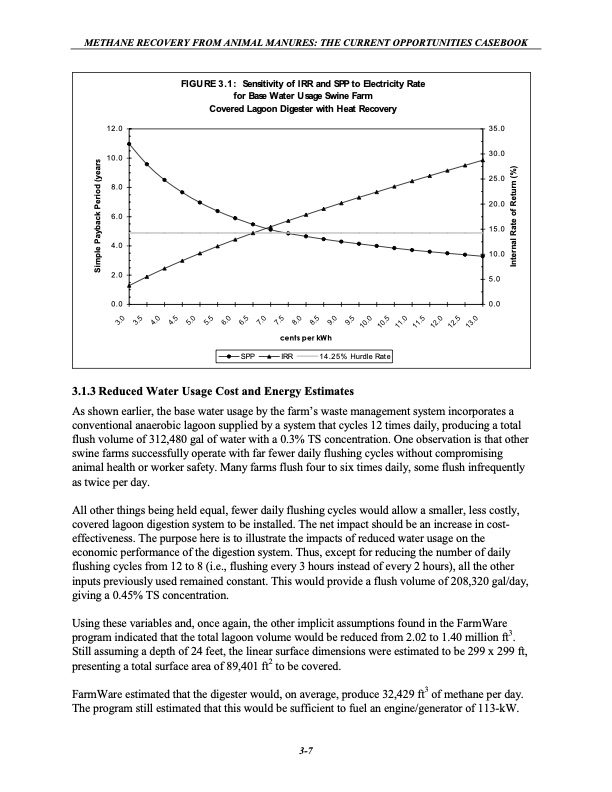

METHANE RECOVERY FROM ANIMAL MANURES: THE CURRENT OPPORTUNITIES CASEBOOK 12.0 10.0 8.0 6.0 4.0 2.0 35.0 30.0 25.0 20.0 15.0 10.0 5.0 FIGURE3.1: SensitivityofIRRandSPPtoElectricityRate for Base Water Usage Swine Farm Covered Lagoon Digester with Heat Recovery 0.0 0.0 SPP cents per kWh IRR 14.25% Hurdle Rate 3.1.3 Reduced Water Usage Cost and Energy Estimates As shown earlier, the base water usage by the farm’s waste management system incorporates a conventional anaerobic lagoon supplied by a system that cycles 12 times daily, producing a total flush volume of 312,480 gal of water with a 0.3% TS concentration. One observation is that other swine farms successfully operate with far fewer daily flushing cycles without compromising animal health or worker safety. Many farms flush four to six times daily, some flush infrequently as twice per day. All other things being held equal, fewer daily flushing cycles would allow a smaller, less costly, covered lagoon digestion system to be installed. The net impact should be an increase in cost- effectiveness. The purpose here is to illustrate the impacts of reduced water usage on the economic performance of the digestion system. Thus, except for reducing the number of daily flushing cycles from 12 to 8 (i.e., flushing every 3 hours instead of every 2 hours), all the other inputs previously used remained constant. This would provide a flush volume of 208,320 gal/day, giving a 0.45% TS concentration. Using these variables and, once again, the other implicit assumptions found in the FarmWare program indicated that the total lagoon volume would be reduced from 2.02 to 1.40 million ft3. Still assuming a depth of 24 feet, the linear surface dimensions were estimated to be 299 x 299 ft, presenting a total surface area of 89,401 ft2 to be covered. FarmWare estimated that the digester would, on average, produce 32,429 ft3 of methane per day. The program still estimated that this would be sufficient to fuel an engine/generator of 113-kW. 3-7 Simple Payback Period (years Internal Rate of Return (%) 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5 13.0PDF Image | Methane Recovery from Animal Manures The Current Opportunities Casebook

PDF Search Title:

Methane Recovery from Animal Manures The Current Opportunities CasebookOriginal File Name Searched:

biogas02.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |