PDF Publication Title:

Text from PDF Page: 071

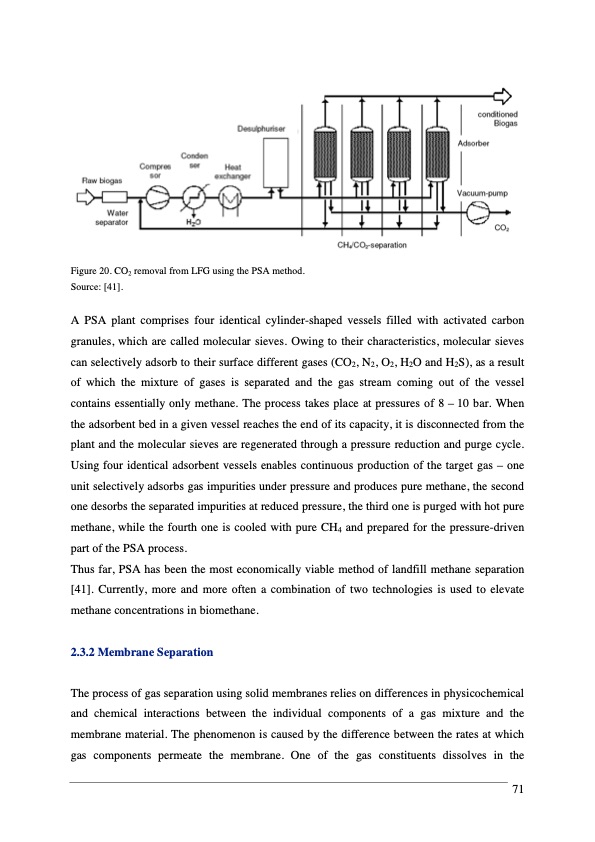

Figure 20. CO2 removal from LFG using the PSA method. Source: [41]. A PSA plant comprises four identical cylinder-shaped vessels filled with activated carbon granules, which are called molecular sieves. Owing to their characteristics, molecular sieves can selectively adsorb to their surface different gases (CO2, N2, O2, H2O and H2S), as a result of which the mixture of gases is separated and the gas stream coming out of the vessel contains essentially only methane. The process takes place at pressures of 8 – 10 bar. When the adsorbent bed in a given vessel reaches the end of its capacity, it is disconnected from the plant and the molecular sieves are regenerated through a pressure reduction and purge cycle. Using four identical adsorbent vessels enables continuous production of the target gas – one unit selectively adsorbs gas impurities under pressure and produces pure methane, the second one desorbs the separated impurities at reduced pressure, the third one is purged with hot pure methane, while the fourth one is cooled with pure CH4 and prepared for the pressure-driven part of the PSA process. Thus far, PSA has been the most economically viable method of landfill methane separation [41]. Currently, more and more often a combination of two technologies is used to elevate methane concentrations in biomethane. 2.3.2 Membrane Separation The process of gas separation using solid membranes relies on differences in physicochemical and chemical interactions between the individual components of a gas mixture and the membrane material. The phenomenon is caused by the difference between the rates at which gas components permeate the membrane. One of the gas constituents dissolves in the 71PDF Image | Landfill Gas Energy Technologies

PDF Search Title:

Landfill Gas Energy TechnologiesOriginal File Name Searched:

1022_LFG-Handbook.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |