PDF Publication Title:

Text from PDF Page: 059

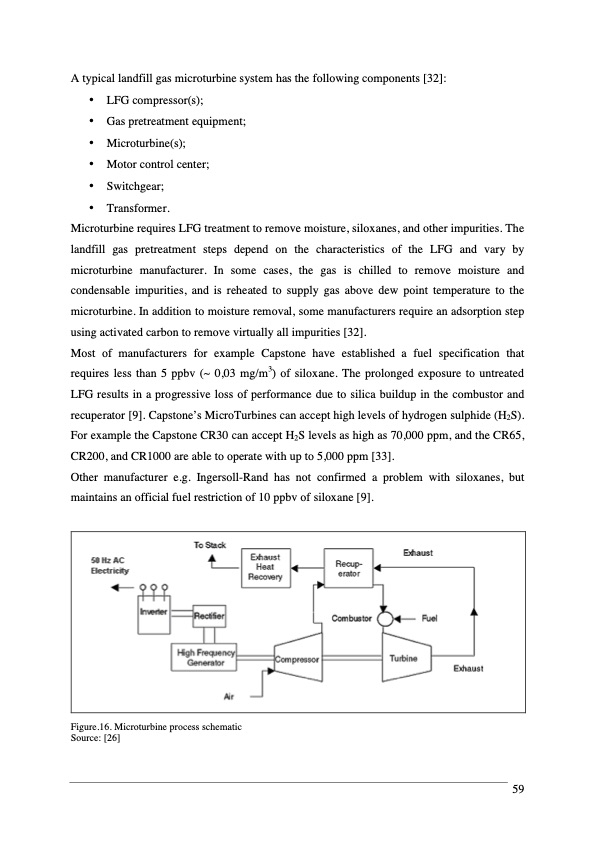

A typical landfill gas microturbine system has the following components [32]: • LFG compressor(s); • Gas pretreatment equipment; • Microturbine(s); • Motor control center; • Switchgear; • Transformer. Microturbine requires LFG treatment to remove moisture, siloxanes, and other impurities. The landfill gas pretreatment steps depend on the characteristics of the LFG and vary by microturbine manufacturer. In some cases, the gas is chilled to remove moisture and condensable impurities, and is reheated to supply gas above dew point temperature to the microturbine. In addition to moisture removal, some manufacturers require an adsorption step using activated carbon to remove virtually all impurities [32]. Most of manufacturers for example Capstone have established a fuel specification that 3 requires less than 5 ppbv (~ 0,03 mg/m ) of siloxane. The prolonged exposure to untreated LFG results in a progressive loss of performance due to silica buildup in the combustor and recuperator [9]. Capstone’s MicroTurbines can accept high levels of hydrogen sulphide (H2S). For example the Capstone CR30 can accept H2S levels as high as 70,000 ppm, and the CR65, CR200, and CR1000 are able to operate with up to 5,000 ppm [33]. Other manufacturer e.g. Ingersoll-Rand has not confirmed a problem with siloxanes, but maintains an official fuel restriction of 10 ppbv of siloxane [9]. Figure.16. Microturbine process schematic Source: [26] 59PDF Image | Landfill Gas Energy Technologies

PDF Search Title:

Landfill Gas Energy TechnologiesOriginal File Name Searched:

1022_LFG-Handbook.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |