PDF Publication Title:

Text from PDF Page: 019

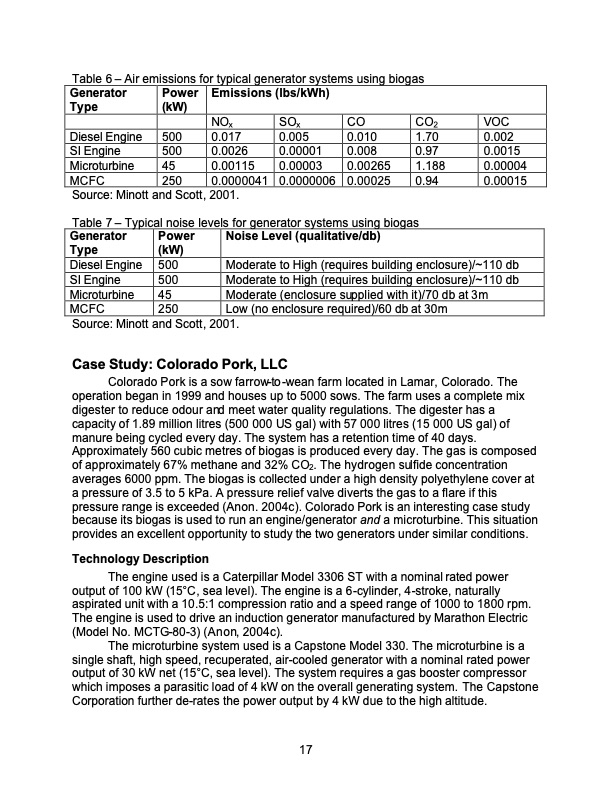

Table 6 – Air emissions for typical generator systems using biogas Generator Type CO CO2 Diesel Engine 0.010 1.70 SI Engine 0.008 0.97 Microturbine 0.00265 1.188 MCFC 0.00025 0.94 Source: Minott and Scott, 2001. Table 7 – Typical noise levels for generator systems using biogas Generator Type Diesel Engine SI Engine Microturbine MCFC Source: Minott and Scott, 2001. Case Study: Colorado Pork, LLC VOC 0.002 0.0015 0.00004 0.00015 Power (kW) Emissions (lbs/kWh) NOx SOx 500 0.017 0.005 500 0.0026 0.00001 45 0.00115 0.00003 250 0.0000041 0.0000006 Power (kW) Noise Level (qualitative/db) 500 Moderate to High (requires building enclosure)/~110 db 500 Moderate to High (requires building enclosure)/~110 db 45 Moderate (enclosure supplied with it)/70 db at 3m 250 Low (no enclosure required)/60 db at 30m Colorado Pork is a sow farrow-to-wean farm located in Lamar, Colorado. The operation began in 1999 and houses up to 5000 sows. The farm uses a complete mix digester to reduce odour and meet water quality regulations. The digester has a capacity of 1.89 million litres (500 000 US gal) with 57 000 litres (15 000 US gal) of manure being cycled every day. The system has a retention time of 40 days. Approximately 560 cubic metres of biogas is produced every day. The gas is composed of approximately 67% methane and 32% CO2. The hydrogen sulfide concentration averages 6000 ppm. The biogas is collected under a high density polyethylene cover at a pressure of 3.5 to 5 kPa. A pressure relief valve diverts the gas to a flare if this pressure range is exceeded (Anon. 2004c). Colorado Pork is an interesting case study because its biogas is used to run an engine/generator and a microturbine. This situation provides an excellent opportunity to study the two generators under similar conditions. Technology Description The engine used is a Caterpillar Model 3306 ST with a nominal rated power output of 100 kW (15°C, sea level). The engine is a 6-cylinder, 4-stroke, naturally aspirated unit with a 10.5:1 compression ratio and a speed range of 1000 to 1800 rpm. The engine is used to drive an induction generator manufactured by Marathon Electric (Model No. MCTG-80-3) (Anon, 2004c). The microturbine system used is a Capstone Model 330. The microturbine is a single shaft, high speed, recuperated, air-cooled generator with a nominal rated power output of 30 kW net (15°C, sea level). The system requires a gas booster compressor which imposes a parasitic load of 4 kW on the overall generating system. The Capstone Corporation further de-rates the power output by 4 kW due to the high altitude. 17PDF Image | Electricity and Heat Production Using Biogas from the Anaerobic Digestion of Livestock Manure - Literature Review

PDF Search Title:

Electricity and Heat Production Using Biogas from the Anaerobic Digestion of Livestock Manure - Literature ReviewOriginal File Name Searched:

fleming_Electricity_and_Heat_from_manure.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |