PDF Publication Title:

Text from PDF Page: 031

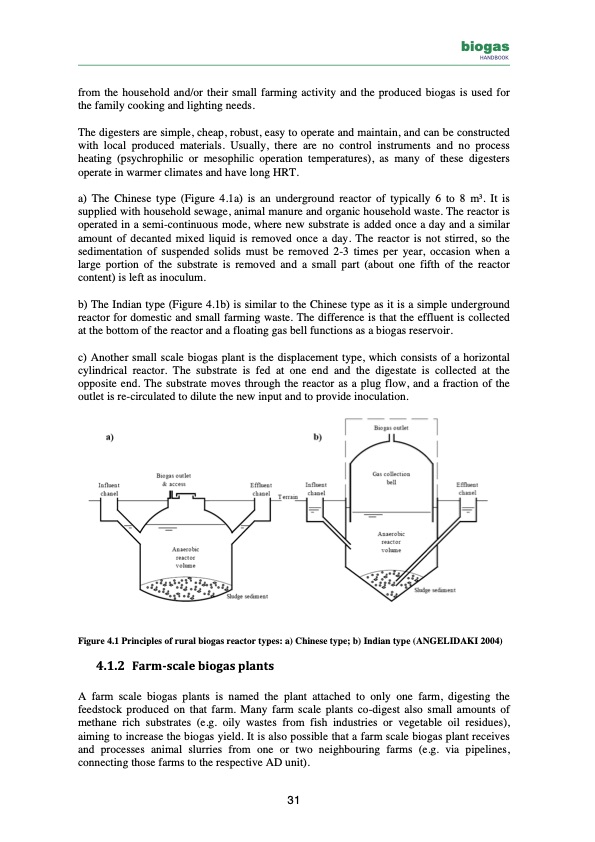

biogas HANDBOOK from the household and/or their small farming activity and the produced biogas is used for the family cooking and lighting needs. The digesters are simple, cheap, robust, easy to operate and maintain, and can be constructed with local produced materials. Usually, there are no control instruments and no process heating (psychrophilic or mesophilic operation temperatures), as many of these digesters operate in warmer climates and have long HRT. a) The Chinese type (Figure 4.1a) is an underground reactor of typically 6 to 8 m3. It is supplied with household sewage, animal manure and organic household waste. The reactor is operated in a semi-continuous mode, where new substrate is added once a day and a similar amount of decanted mixed liquid is removed once a day. The reactor is not stirred, so the sedimentation of suspended solids must be removed 2-3 times per year, occasion when a large portion of the substrate is removed and a small part (about one fifth of the reactor content) is left as inoculum. b) The Indian type (Figure 4.1b) is similar to the Chinese type as it is a simple underground reactor for domestic and small farming waste. The difference is that the effluent is collected at the bottom of the reactor and a floating gas bell functions as a biogas reservoir. c) Another small scale biogas plant is the displacement type, which consists of a horizontal cylindrical reactor. The substrate is fed at one end and the digestate is collected at the opposite end. The substrate moves through the reactor as a plug flow, and a fraction of the outlet is re-circulated to dilute the new input and to provide inoculation. Figure 4.1 Principles of rural biogas reactor types: a) Chinese type; b) Indian type (ANGELIDAKI 2004) 4.1.2 Farm-scalebiogasplants A farm scale biogas plants is named the plant attached to only one farm, digesting the feedstock produced on that farm. Many farm scale plants co-digest also small amounts of methane rich substrates (e.g. oily wastes from fish industries or vegetable oil residues), aiming to increase the biogas yield. It is also possible that a farm scale biogas plant receives and processes animal slurries from one or two neighbouring farms (e.g. via pipelines, connecting those farms to the respective AD unit). 31PDF Image | biogas HANDBOOK

PDF Search Title:

biogas HANDBOOKOriginal File Name Searched:

BiogasHandbook.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |