PDF Publication Title:

Text from PDF Page: 051

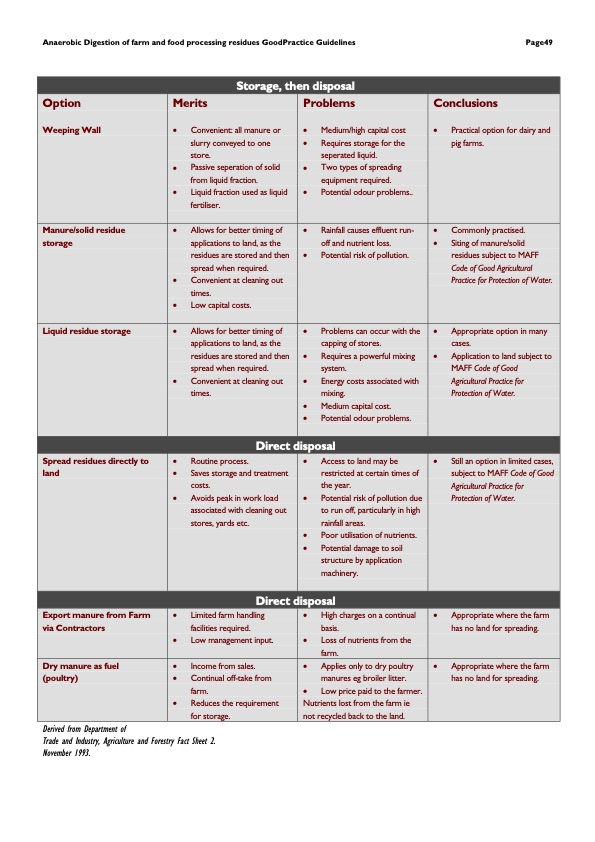

Anaerobic Digestion of farm and food processing residues GoodPractice Guidelines Page49 Storage, then disposal Option Weeping Wall Merits • Convenient: all manure or slurry conveyed to one store. • Passive seperation of solid from liquid fraction. • Liquid fraction used as liquid fertiliser. Problems • Medium/high capital cost • Requires storage for the seperated liquid. • Two types of spreading equipment required. • Potential odour problems.. Conclusions • Practical option for dairy and pig farms. Manure/solid residue storage • Allows for better timing of applications to land, as the residues are stored and then spread when required. • Convenient at cleaning out times. • Low capital costs. • Rainfall causes effluent run- off and nutrient loss. • Potential risk of pollution. • Commonly practised. • Siting of manure/solid residues subject to MAFF Code of Good Agricultural Practice for Protection of Water. Liquid residue storage • Allows for better timing of applications to land, as the residues are stored and then spread when required. • Convenient at cleaning out times. • Problems can occur with the capping of stores. • Requires a powerful mixing system. • Energy costs associated with mixing. • Medium capital cost. • Potential odour problems. • Appropriate option in many cases. • Application to land subject to MAFF Code of Good Agricultural Practice for Protection of Water. Direct disposal Spread residues directly to land • Routine process. • Saves storage and treatment costs. • Avoids peak in work load associated with cleaning out stores, yards etc. • Access to land may be restricted at certain times of the year. • Potential risk of pollution due to run off, particularly in high rainfall areas. • Poor utilisation of nutrients. • Potential damage to soil structure by application machinery. • Still an option in limited cases, subject to MAFF Code of Good Agricultural Practice for Protection of Water. Direct disposal Export manure from Farm via Contractors • Limited farm handling facilities required. • Low management input. • High charges on a continual basis. • Loss of nutrients from the farm. • Appropriate where the farm has no land for spreading. Dry manure as fuel (poultry) • Income from sales. • Continual off-take from farm. • Reduces the requirement for storage. • Applies only to dry poultry manures eg broiler litter. • Low price paid to the farmer. Nutrients lost from the farm ie not recycled back to the land. • Appropriate where the farm has no land for spreading. Derived from Department of Trade and Industry, Agriculture and Forestry Fact Sheet 2. November 1993.PDF Image | Anaerobic Digestion Of farm and food Processing residues The development of a sustainable industry

PDF Search Title:

Anaerobic Digestion Of farm and food Processing residues The development of a sustainable industryOriginal File Name Searched:

biogas10.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |