PDF Publication Title:

Text from PDF Page: 004

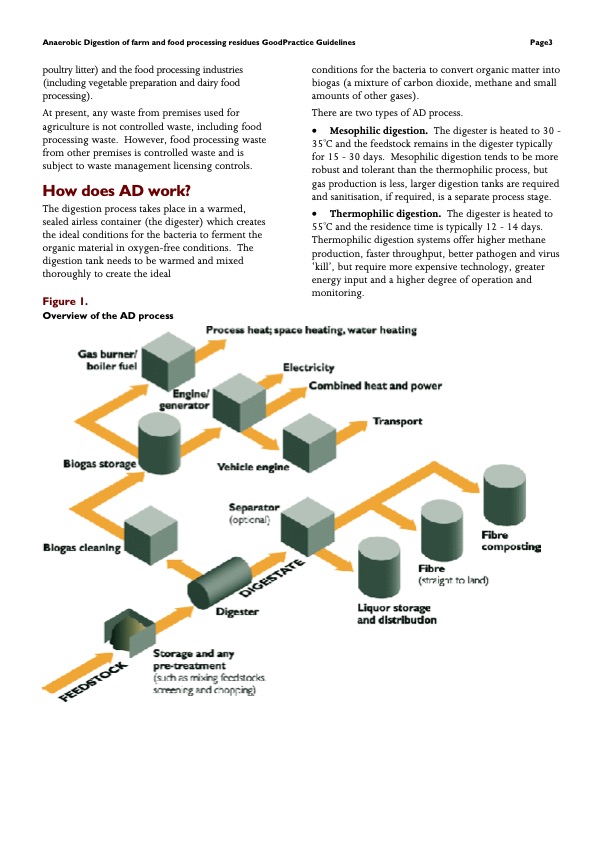

Anaerobic Digestion of farm and food processing residues GoodPractice Guidelines Page3 poultry litter) and the food processing industries (including vegetable preparation and dairy food processing). At present, any waste from premises used for agriculture is not controlled waste, including food processing waste. However, food processing waste from other premises is controlled waste and is subject to waste management licensing controls. How does AD work? The digestion process takes place in a warmed, sealed airless container (the digester) which creates the ideal conditions for the bacteria to ferment the organic material in oxygen-free conditions. The digestion tank needs to be warmed and mixed thoroughly to create the ideal Figure 1. Overview of the AD process conditions for the bacteria to convert organic matter into biogas (a mixture of carbon dioxide, methane and small amounts of other gases). There are two types of AD process. • Mesophilic digestion. The digester is heated to 30 - 35oC and the feedstock remains in the digester typically for 15 - 30 days. Mesophilic digestion tends to be more robust and tolerant than the thermophilic process, but gas production is less, larger digestion tanks are required and sanitisation, if required, is a separate process stage. • Thermophilic digestion. The digester is heated to 55oC and the residence time is typically 12 - 14 days. Thermophilic digestion systems offer higher methane production, faster throughput, better pathogen and virus ‘kill’, but require more expensive technology, greater energy input and a higher degree of operation and monitoring.PDF Image | Anaerobic Digestion Of farm and food Processing residues The development of a sustainable industry

PDF Search Title:

Anaerobic Digestion Of farm and food Processing residues The development of a sustainable industryOriginal File Name Searched:

biogas10.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |