PDF Publication Title:

Text from PDF Page: 008

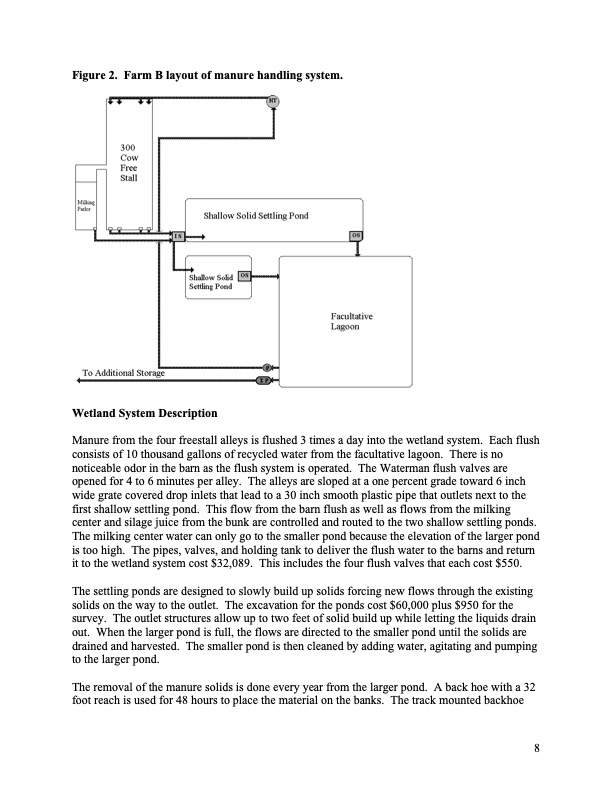

Figure 2. Farm B layout of manure handling system. Wetland System Description Manure from the four freestall alleys is flushed 3 times a day into the wetland system. Each flush consists of 10 thousand gallons of recycled water from the facultative lagoon. There is no noticeable odor in the barn as the flush system is operated. The Waterman flush valves are opened for 4 to 6 minutes per alley. The alleys are sloped at a one percent grade toward 6 inch wide grate covered drop inlets that lead to a 30 inch smooth plastic pipe that outlets next to the first shallow settling pond. This flow from the barn flush as well as flows from the milking center and silage juice from the bunk are controlled and routed to the two shallow settling ponds. The milking center water can only go to the smaller pond because the elevation of the larger pond is too high. The pipes, valves, and holding tank to deliver the flush water to the barns and return it to the wetland system cost $32,089. This includes the four flush valves that each cost $550. The settling ponds are designed to slowly build up solids forcing new flows through the existing solids on the way to the outlet. The excavation for the ponds cost $60,000 plus $950 for the survey. The outlet structures allow up to two feet of solid build up while letting the liquids drain out. When the larger pond is full, the flows are directed to the smaller pond until the solids are drained and harvested. The smaller pond is then cleaned by adding water, agitating and pumping to the larger pond. The removal of the manure solids is done every year from the larger pond. A back hoe with a 32 foot reach is used for 48 hours to place the material on the banks. The track mounted backhoe 8PDF Image | ANAEROBIC DIGESTION AND WETLAND TREATMENT CASE STUDY: COMPARING TWO MANURE ODOR CONTROL SYSTEMS FOR DAIRY FARMS

PDF Search Title:

ANAEROBIC DIGESTION AND WETLAND TREATMENT CASE STUDY: COMPARING TWO MANURE ODOR CONTROL SYSTEMS FOR DAIRY FARMSOriginal File Name Searched:

biogas07.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |