PDF Publication Title:

Text from PDF Page: 006

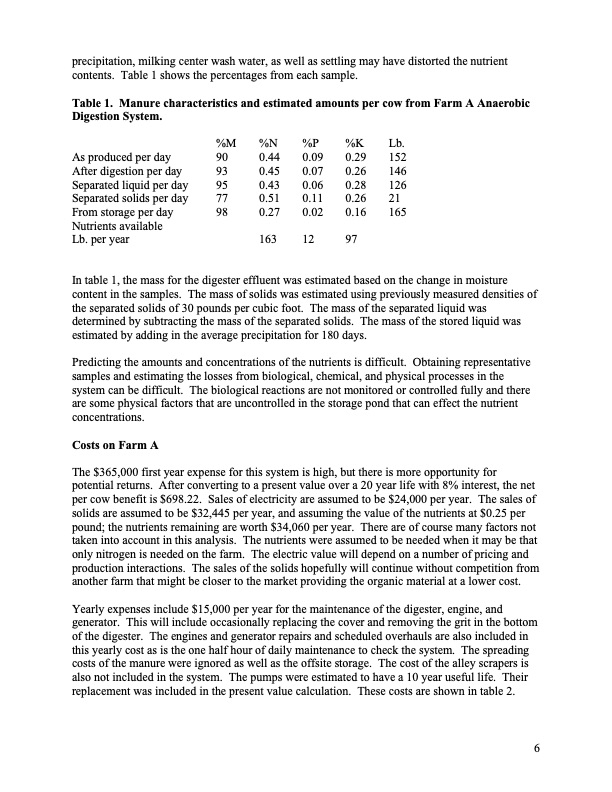

precipitation, milking center wash water, as well as settling may have distorted the nutrient contents. Table 1 shows the percentages from each sample. Table 1. Manure characteristics and estimated amounts per cow from Farm A Anaerobic Digestion System. %M %N %P 90 0.44 0.09 93 0.45 0.07 95 0.43 0.06 77 0.51 0.11 98 0.27 0.02 %K Lb. 0.29 152 0.26 146 0.28 126 0.26 21 0.16 165 As produced per day After digestion per day Separated liquid per day Separated solids per day From storage per day Nutrients available Lb. per year In table 1, the mass for the digester effluent content in the samples. The mass of solids was estimated using previously measured densities of the separated solids of 30 pounds per cubic foot. The mass of the separated liquid was determined by subtracting the mass of the separated solids. The mass of the stored liquid was estimated by adding in the average precipitation for 180 days. Predicting the amounts and concentrations of the nutrients is difficult. Obtaining representative samples and estimating the losses from biological, chemical, and physical processes in the system can be difficult. The biological reactions are not monitored or controlled fully and there are some physical factors that are uncontrolled in the storage pond that can effect the nutrient concentrations. Costs on Farm A The $365,000 first year expense for this system is high, but there is more opportunity for potential returns. After converting to a present value over a 20 year life with 8% interest, the net per cow benefit is $698.22. Sales of electricity are assumed to be $24,000 per year. The sales of solids are assumed to be $32,445 per year, and assuming the value of the nutrients at $0.25 per pound; the nutrients remaining are worth $34,060 per year. There are of course many factors not taken into account in this analysis. The nutrients were assumed to be needed when it may be that only nitrogen is needed on the farm. The electric value will depend on a number of pricing and production interactions. The sales of the solids hopefully will continue without competition from another farm that might be closer to the market providing the organic material at a lower cost. Yearly expenses include $15,000 per year for the maintenance of the digester, engine, and generator. This will include occasionally replacing the cover and removing the grit in the bottom of the digester. The engines and generator repairs and scheduled overhauls are also included in this yearly cost as is the one half hour of daily maintenance to check the system. The spreading costs of the manure were ignored as well as the offsite storage. The cost of the alley scrapers is also not included in the system. The pumps were estimated to have a 10 year useful life. Their replacement was included in the present value calculation. These costs are shown in table 2. 163 12 97 was estimated based on the change in moisture 6PDF Image | ANAEROBIC DIGESTION AND WETLAND TREATMENT CASE STUDY: COMPARING TWO MANURE ODOR CONTROL SYSTEMS FOR DAIRY FARMS

PDF Search Title:

ANAEROBIC DIGESTION AND WETLAND TREATMENT CASE STUDY: COMPARING TWO MANURE ODOR CONTROL SYSTEMS FOR DAIRY FARMSOriginal File Name Searched:

biogas07.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |