PDF Publication Title:

Text from PDF Page: 003

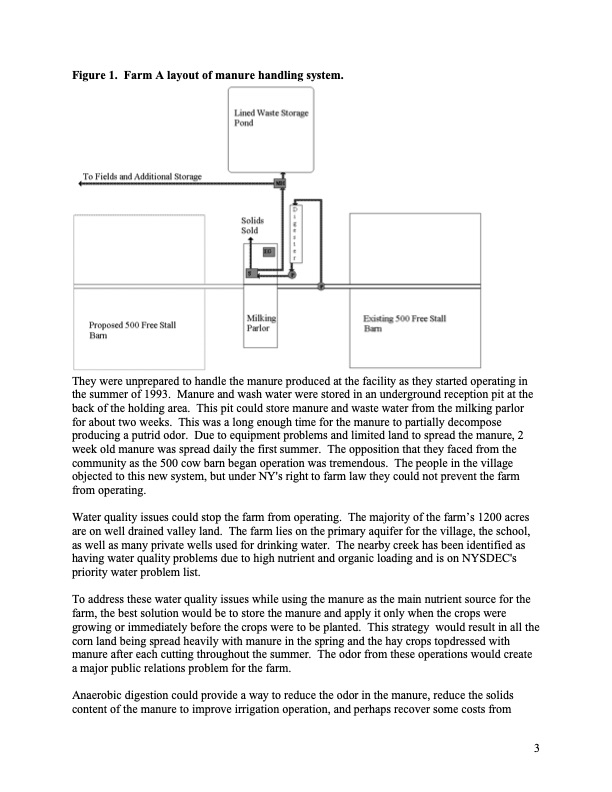

Figure 1. Farm A layout of manure handling system. They were unprepared to handle the manure produced at the facility as they started operating in the summer of 1993. Manure and wash water were stored in an underground reception pit at the back of the holding area. This pit could store manure and waste water from the milking parlor for about two weeks. This was a long enough time for the manure to partially decompose producing a putrid odor. Due to equipment problems and limited land to spread the manure, 2 week old manure was spread daily the first summer. The opposition that they faced from the community as the 500 cow barn began operation was tremendous. The people in the village objected to this new system, but under NY's right to farm law they could not prevent the farm from operating. Water quality issues could stop the farm from operating. The majority of the farm’s 1200 acres are on well drained valley land. The farm lies on the primary aquifer for the village, the school, as well as many private wells used for drinking water. The nearby creek has been identified as having water quality problems due to high nutrient and organic loading and is on NYSDEC's priority water problem list. To address these water quality issues while using the manure as the main nutrient source for the farm, the best solution would be to store the manure and apply it only when the crops were growing or immediately before the crops were to be planted. This strategy would result in all the corn land being spread heavily with manure in the spring and the hay crops topdressed with manure after each cutting throughout the summer. The odor from these operations would create a major public relations problem for the farm. Anaerobic digestion could provide a way to reduce the odor in the manure, reduce the solids content of the manure to improve irrigation operation, and perhaps recover some costs from 3PDF Image | ANAEROBIC DIGESTION AND WETLAND TREATMENT CASE STUDY: COMPARING TWO MANURE ODOR CONTROL SYSTEMS FOR DAIRY FARMS

PDF Search Title:

ANAEROBIC DIGESTION AND WETLAND TREATMENT CASE STUDY: COMPARING TWO MANURE ODOR CONTROL SYSTEMS FOR DAIRY FARMSOriginal File Name Searched:

biogas07.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |