PDF Publication Title:

Text from PDF Page: 005

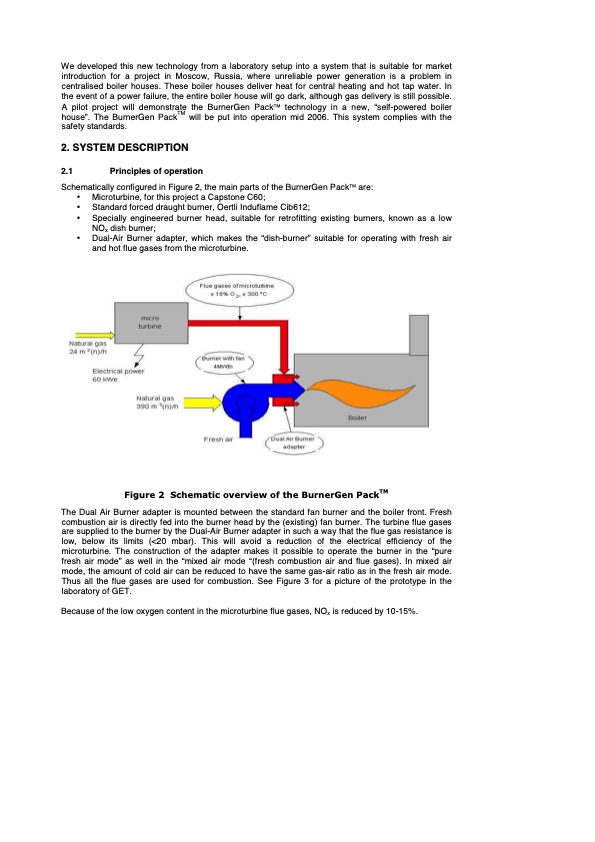

We developed this new technology from a laboratory setup into a system that is suitable for market introduction for a project in Moscow, Russia, where unreliable power generation is a problem in centralised boiler houses. These boiler houses deliver heat for central heating and hot tap water. In the event of a power failure, the entire boiler house will go dark, although gas delivery is still possible. A pilot project will demonstrate the BurnerGen Pack technology in a new, “self-powered boiler TM house”. The BurnerGen Pack will be put into operation mid 2006. This system complies with the safety standards. 2. SYSTEM DESCRIPTION 2.1 Principles of operation Schematically configured in Figure 2, the main parts of the BurnerGen Pack are: • Microturbine, for this project a Capstone C60; • Standard forced draught burner, Oertli Induflame Cib612; • Specially engineered burner head, suitable for retrofitting existing burners, known as a low NOx dish burner; • Dual-Air Burner adapter, which makes the “dish-burner” suitable for operating with fresh air and hot flue gases from the microturbine. Figure 2 Schematic overview of the BurnerGen PackTM The Dual Air Burner adapter is mounted between the standard fan burner and the boiler front. Fresh combustion air is directly fed into the burner head by the (existing) fan burner. The turbine flue gases are supplied to the burner by the Dual-Air Burner adapter in such a way that the flue gas resistance is low, below its limits (<20 mbar). This will avoid a reduction of the electrical efficiency of the microturbine. The construction of the adapter makes it possible to operate the burner in the “pure fresh air mode” as well in the “mixed air mode “(fresh combustion air and flue gases). In mixed air mode, the amount of cold air can be reduced to have the same gas-air ratio as in the fresh air mode. Thus all the flue gases are used for combustion. See Figure 3 for a picture of the prototype in the laboratory of GET. Because of the low oxygen content in the microturbine flue gases, NOx is reduced by 10-15%.PDF Image | SELF POWERED BOILER HOUSE: A NOVEL METHOD FOR INCORPORATING A MICRO TURBINE INTO AN EXISTING DOMESTIC ENERGY INFRASTRUCTURE FOR HEAT SUPPLY TO HOUSEHOLDS

PDF Search Title:

SELF POWERED BOILER HOUSE: A NOVEL METHOD FOR INCORPORATING A MICRO TURBINE INTO AN EXISTING DOMESTIC ENERGY INFRASTRUCTURE FOR HEAT SUPPLY TO HOUSEHOLDSOriginal File Name Searched:

add10219.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |