PDF Publication Title:

Text from PDF Page: 002

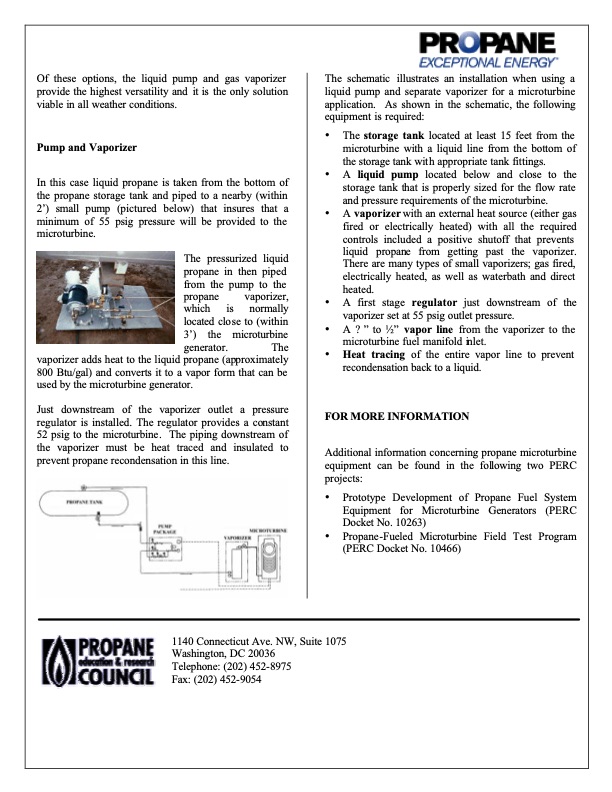

Of these options, the liquid pump and gas vaporizer provide the highest versatility and it is the only solution viable in all weather conditions. Pump and Vaporizer In this case liquid propane is taken from the bottom of the propane storage tank and piped to a nearby (within 2’) small pump (pictured below) that insures that a minimum of 55 psig pressure will be provided to the microturbine. The pressurized liquid propane in then piped from the pump to the propane vaporizer, which is normally located close to (within 3’) the microturbine generator. The vaporizer adds heat to the liquid propane (approximately 800 Btu/gal) and converts it to a vapor form that can be used by the microturbine generator. Just downstream of the vaporizer outlet a pressure regulator is installed. The regulator provides a constant 52 psig to the microturbine. The piping downstream of the vaporizer must be heat traced and insulated to prevent propane recondensation in this line. The schematic illustrates an installation when using a liquid pump and separate vaporizer for a microturbine application. As shown in the schematic, the following equipment is required: • The storage tank located at least 15 feet from the microturbine with a liquid line from the bottom of the storage tank with appropriate tank fittings. • A liquid pump located below and close to the storage tank that is properly sized for the flow rate and pressure requirements of the microturbine. • A vaporizer with an external heat source (either gas fired or electrically heated) with all the required controls included a positive shutoff that prevents liquid propane from getting past the vaporizer. There are many types of small vaporizers; gas fired, electrically heated, as well as waterbath and direct heated. • A first stage regulator just downstream of the vaporizer set at 55 psig outlet pressure. • A ? ” to 1⁄2” vapor line from the vaporizer to the microturbine fuel manifold inlet. • Heat tracing of the entire vapor line to prevent recondensation back to a liquid. FOR MORE INFORMATION Additional information concerning propane microturbine equipment can be found in the following two PERC projects: • Prototype Development of Propane Fuel System Equipment for Microturbine Generators (PERC Docket No. 10263) • Propane -Fueled Microturbine Field Test Program (PERC Docket No. 10466) 1140 Connecticut Ave. NW, Suite 1075 Washington, DC 20036 Telephone: (202) 452-8975 Fax: (202) 452-9054PDF Image | PROPANE-FUELED MICROTURBINES

PDF Search Title:

PROPANE-FUELED MICROTURBINESOriginal File Name Searched:

REP_10466_Microturbines_Brochure.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |