PDF Publication Title:

Text from PDF Page: 002

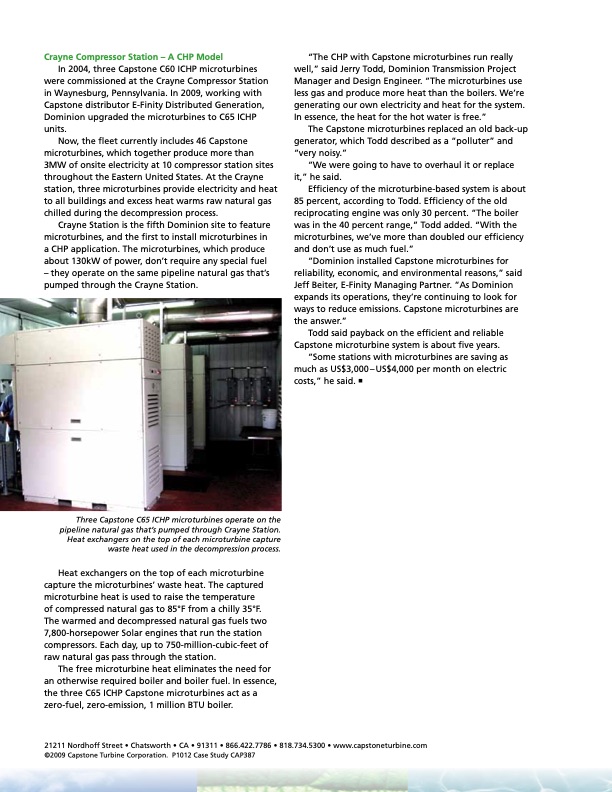

Crayne Compressor Station – A CHP Model In 2004, three Capstone C60 ICHP microturbines were commissioned at the Crayne Compressor Station in Waynesburg, Pennsylvania. In 2009, working with Capstone distributor E-Finity Distributed Generation, Dominion upgraded the microturbines to C65 ICHP units. Now, the fleet currently includes 46 Capstone microturbines, which together produce more than 3MW of onsite electricity at 10 compressor station sites throughout the Eastern United States. At the Crayne station, three microturbines provide electricity and heat to all buildings and excess heat warms raw natural gas chilled during the decompression process. Crayne Station is the fifth Dominion site to feature microturbines, and the first to install microturbines in a CHP application. The microturbines, which produce about 130kW of power, don’t require any special fuel – they operate on the same pipeline natural gas that’s pumped through the Crayne Station. “The CHP with Capstone microturbines run really well,” said Jerry Todd, Dominion Transmission Project Manager and Design Engineer. “The microturbines use less gas and produce more heat than the boilers. We’re generating our own electricity and heat for the system. In essence, the heat for the hot water is free.” The Capstone microturbines replaced an old back-up generator, which Todd described as a “polluter” and “very noisy.” “We were going to have to overhaul it or replace it,” he said. Efficiency of the microturbine-based system is about 85 percent, according to Todd. Efficiency of the old reciprocating engine was only 30 percent. “The boiler was in the 40 percent range,” Todd added. “With the microturbines, we’ve more than doubled our efficiency and don’t use as much fuel.” “Dominion installed Capstone microturbines for reliability, economic, and environmental reasons,” said Jeff Beiter, E-Finity Managing Partner. “As Dominion expands its operations, they’re continuing to look for ways to reduce emissions. Capstone microturbines are the answer.” Todd said payback on the efficient and reliable Capstone microturbine system is about five years. “Some stations with microturbines are saving as much as US$3,000 – US$4,000 per month on electric costs,” he said. Three Capstone C65 ICHP microturbines operate on the pipeline natural gas that’s pumped through Crayne Station. Heat exchangers on the top of each microturbine capture waste heat used in the decompression process. Heat exchangers on the top of each microturbine capture the microturbines’ waste heat. The captured microturbine heat is used to raise the temperature of compressed natural gas to 85°F from a chilly 35°F. The warmed and decompressed natural gas fuels two 7,800-horsepower Solar engines that run the station compressors. Each day, up to 750-million-cubic-feet of raw natural gas pass through the station. The free microturbine heat eliminates the need for an otherwise required boiler and boiler fuel. In essence, the three C65 ICHP Capstone microturbines act as a zero-fuel, zero-emission, 1 million BTU boiler. 21211 Nordhoff Street • Chatsworth • CA • 91311 • 866.422.7786 • 818.734.5300 • www.capstoneturbine.com ©2009 Capstone Turbine Corporation. P1012 Case Study CAP387PDF Image | Oil & Gas Dominion Transmission Crayne Compressor Station

PDF Search Title:

Oil & Gas Dominion Transmission Crayne Compressor StationOriginal File Name Searched:

CS_CAP387_Dominion_lowres.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |