PDF Publication Title:

Text from PDF Page: 002

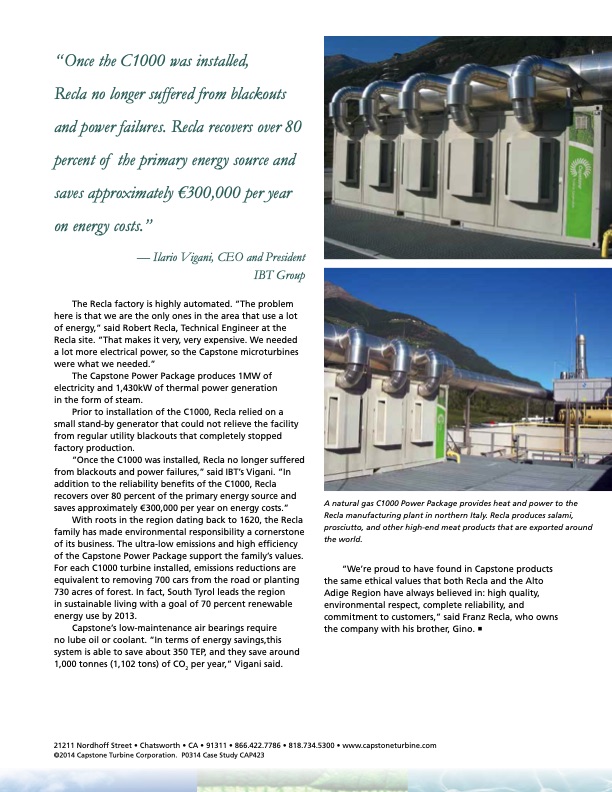

“ Once the C1000 was installed, Recla no longer suffered from blackouts and power failures. Recla recovers over 80 percent of the primary energy source and saves approximately €300,000 per year on energy costs.” — Ilario Vigani, CEO and President IBT Group The Recla factory is highly automated. “The problem here is that we are the only ones in the area that use a lot of energy,” said Robert Recla, Technical Engineer at the Recla site. “That makes it very, very expensive. We needed a lot more electrical power, so the Capstone microturbines were what we needed.” The Capstone Power Package produces 1MW of electricity and 1,430kW of thermal power generation in the form of steam. Prior to installation of the C1000, Recla relied on a small stand-by generator that could not relieve the facility from regular utility blackouts that completely stopped factory production. “Once the C1000 was installed, Recla no longer suffered from blackouts and power failures,” said IBT’s Vigani. “In addition to the reliability benefits of the C1000, Recla recovers over 80 percent of the primary energy source and saves approximately €300,000 per year on energy costs.” With roots in the region dating back to 1620, the Recla family has made environmental responsibility a cornerstone of its business. The ultra-low emissions and high efficiency of the Capstone Power Package support the family’s values. For each C1000 turbine installed, emissions reductions are equivalent to removing 700 cars from the road or planting 730 acres of forest. In fact, South Tyrol leads the region in sustainable living with a goal of 70 percent renewable energy use by 2013. Capstone’s low-maintenance air bearings require no lube oil or coolant. “In terms of energy savings,this system is able to save about 350 TEP, and they save around 1,000 tonnes (1,102 tons) of CO2 per year,” Vigani said. A natural gas C1000 Power Package provides heat and power to the Recla manufacturing plant in northern Italy. Recla produces salami, prosciutto, and other high-end meat products that are exported around the world. “We’re proud to have found in Capstone products the same ethical values that both Recla and the Alto Adige Region have always believed in: high quality, environmental respect, complete reliability, and commitment to customers,” said Franz Recla, who owns the company with his brother, Gino. 21211 Nordhoff Street • Chatsworth • CA • 91311 • 866.422.7786 • 818.734.5300 • www.capstoneturbine.com ©2014 Capstone Turbine Corporation. P0314 Case Study CAP423PDF Image | Manufacturing Recla Manufacturing Plant

PDF Search Title:

Manufacturing Recla Manufacturing PlantOriginal File Name Searched:

CS_CAP423_Recla_lowres.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |