PDF Publication Title:

Text from PDF Page: 001

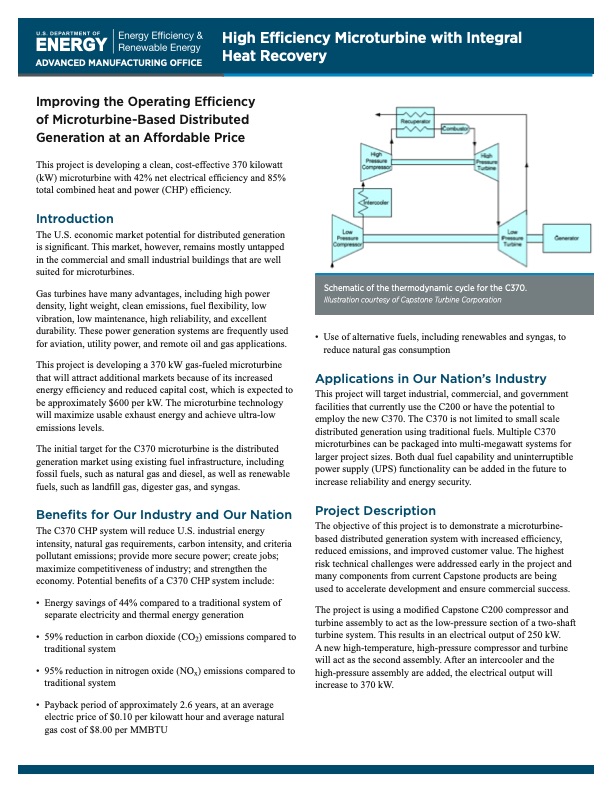

ADVANCED MANUFACTURING OFFICE High Efficiency Microturbine with Integral Heat Recovery Improving the Operating Efficiency of Microturbine-Based Distributed Generation at an Affordable Price This project is developing a clean, cost-effective 370 kilowatt (kW) microturbine with 42% net electrical efficiency and 85% total combined heat and power (CHP) efficiency. Introduction The U.S. economic market potential for distributed generation is significant. This market, however, remains mostly untapped in the commercial and small industrial buildings that are well suited for microturbines. Gas turbines have many advantages, including high power density, light weight, clean emissions, fuel flexibility, low vibration, low maintenance, high reliability, and excellent durability. These power generation systems are frequently used for aviation, utility power, and remote oil and gas applications. This project is developing a 370 kW gas-fueled microturbine that will attract additional markets because of its increased energy efficiency and reduced capital cost, which is expected to be approximately $600 per kW. The microturbine technology will maximize usable exhaust energy and achieve ultra-low emissions levels. The initial target for the C370 microturbine is the distributed generation market using existing fuel infrastructure, including fossil fuels, such as natural gas and diesel, as well as renewable fuels, such as landfill gas, digester gas, and syngas. Benefits for Our Industry and Our Nation The C370 CHP system will reduce U.S. industrial energy intensity, natural gas requirements, carbon intensity, and criteria pollutant emissions; provide more secure power; create jobs; maximize competitiveness of industry; and strengthen the economy. Potential benefits of a C370 CHP system include: • Energy savings of 44% compared to a traditional system of separate electricity and thermal energy generation • 59% reduction in carbon dioxide (CO2) emissions compared to traditional system • 95% reduction in nitrogen oxide (NO ) emissions compared to traditional system x • Payback period of approximately 2.6 years, at an average electric price of $0.10 per kilowatt hour and average natural gas cost of $8.00 per MMBTU • Use of alternative fuels, including renewables and syngas, to reduce natural gas consumption Applications in Our Nation’s Industry This project will target industrial, commercial, and government facilities that currently use the C200 or have the potential to employ the new C370. The C370 is not limited to small scale distributed generation using traditional fuels. Multiple C370 microturbines can be packaged into multi-megawatt systems for larger project sizes. Both dual fuel capability and uninterruptible power supply (UPS) functionality can be added in the future to increase reliability and energy security. Project Description The objective of this project is to demonstrate a microturbine- based distributed generation system with increased efficiency, reduced emissions, and improved customer value. The highest risk technical challenges were addressed early in the project and many components from current Capstone products are being used to accelerate development and ensure commercial success. The project is using a modified Capstone C200 compressor and turbine assembly to act as the low-pressure section of a two-shaft turbine system. This results in an electrical output of 250 kW. A new high-temperature, high-pressure compressor and turbine will act as the second assembly. After an intercooler and the high-pressure assembly are added, the electrical output will increase to 370 kW. SEITIC NAELC Schematic of the thermodynamic cycle for the C370. Illustration courtesy of Capstone Turbine CorporationPDF Image | High Efficiency Microturbine with Integral Heat Recovery

PDF Search Title:

High Efficiency Microturbine with Integral Heat RecoveryOriginal File Name Searched:

capstone.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |