PDF Publication Title:

Text from PDF Page: 055

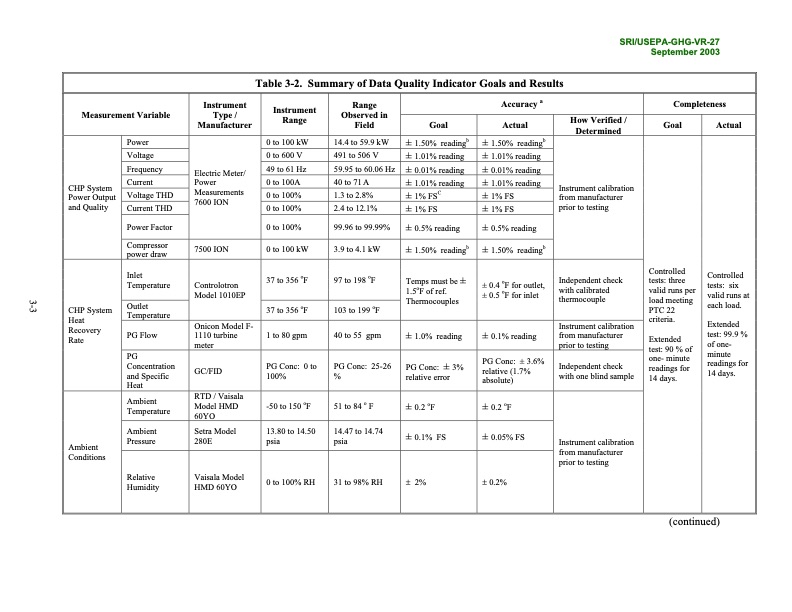

3-3 Measurement Variable How Verified / Determined CHP System Power Output and Quality Power Voltage Frequency Current Voltage THD Current THD Electric Meter/ Power Measurements 7600 ION 0 to 100 kW 0 to 600 V 49 to 61 Hz 0 to 100A 14.4 to 59.9 kW 491 to 506 V 59.95 to 60.06 Hz 40 to 71A ± 1.50% readingb ± 1.01% reading ± 0.01% reading ± 1.01% reading ± 1% FSC ± 1.50% readingb ± 1.01% reading ± 0.01% reading ± 1.01% reading ±1%FS ±1%FS Instrument calibration from manufacturer prior to testing CHP System Heat Recovery Rate Outlet Temperature o F o 103to199 F Ambient Conditions Ambient Pressure Setra Model 280E 13.80 to 14.50 psia 14.47 to 14.74 psia Instrument calibration from manufacturer prior to testing Power Factor 0 to 100% 0 to 100 kW 99.96 to 99.99% 3.9 to 4.1 kW ± 0.5% reading ± 1.50% readingb Compressor power draw 7500 ION ± 1.50% readingb Inlet Temperature Controlotron Model 1010EP 37 to 356 o F o 97to198 F Temps must be ± 1.5oF of ref. Thermocouples ± 0.4 oF for outlet, ± 0.5 oF for inlet Independent check with calibrated thermocouple Controlled tests: three valid runs per load meeting PTC 22 criteria. Controlled tests: six valid runs at each load. PG Flow Onicon Model F- 1110 turbine meter 37 to 356 1 to 80 gpm 40 to 55 gpm ± 1.0% reading ± 0.1% reading Instrument calibration from manufacturer prior to testing Extended test: 90 % of one- minute readings for 14 days. Extended test: 99.9 % of one- minute readings for 14 days. PG Concentration and Specific Heat GC/FID PG Conc: 0 to 100% PG Conc: 25-26 % PG Conc: ± 3% relative error PG Conc: ± 3.6% relative (1.7% absolute) Independent check with one blind sample Ambient Temperature RTD / Vaisala ModelHMD 60YO o -50to150 F o 51to84 F ±0.2oF ± 0.1% FS ±0.2oF ± 0.05% FS Relative Humidity Vaisala Model HMD 60YO 0 to 100% RH 31 to 98% RH ± 2% ± 0.2% Instrument Type / Manufacturer Instrument Range Range Observed in Field Accuracy a Actual Completeness Table 3-2. Summary of Data Quality Indicator Goals and Results 0 to 100% 0 to 100% 1.3 to 2.8% 2.4 to 12.1% ± 1% FS ± 0.5% reading 3-3 Goal Goal Actual SRI/USEPA-GHG-VR-27 September 2003 (continued)PDF Image | Environmental Technology Verification Report

PDF Search Title:

Environmental Technology Verification ReportOriginal File Name Searched:

Capstone-ETV-Report.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |