PDF Publication Title:

Text from PDF Page: 005

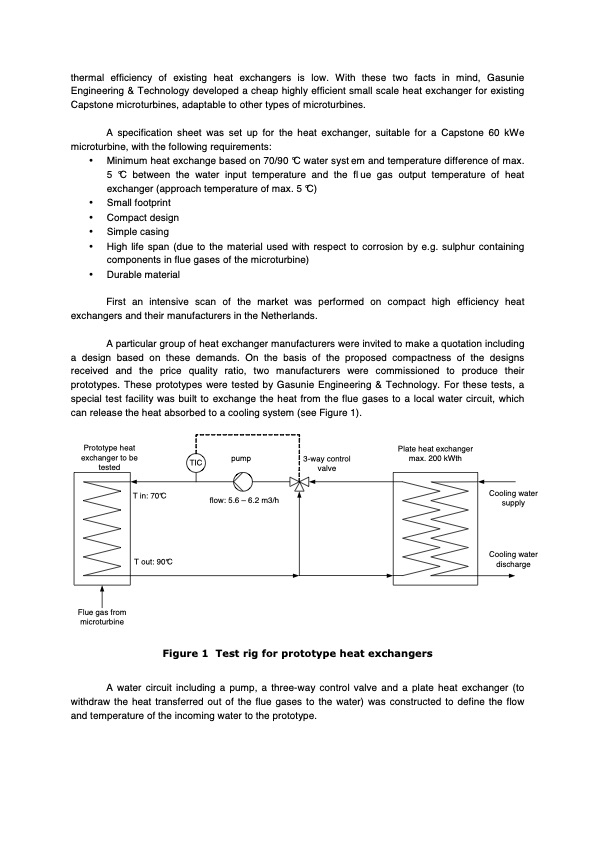

thermal efficiency of existing heat exchangers is low. With these two facts in mind, Gasunie Engineering & Technology developed a cheap highly efficient small scale heat exchanger for existing Capstone microturbines, adaptable to other types of microturbines. A specification sheet was set up for the heat exchanger, suitable for a Capstone 60 kWe microturbine, with the following requirements: • Minimum heat exchange based on 70/90 °C water syst em and temperature difference of max. 5 °C between the water input temperature and the flue gas output temperature of heat exchanger (approach temperature of max. 5 °C) • Small footprint • Compact design • Simple casing • High life span (due to the material used with respect to corrosion by e.g. sulphur containing components in flue gases of the microturbine) • Durable material First an intensive scan of the market was performed on compact high efficiency heat exchangers and their manufacturers in the Netherlands. A particular group of heat exchanger manufacturers were invited to make a quotation including a design based on these demands. On the basis of the proposed compactness of the designs received and the price quality ratio, two manufacturers were commissioned to produce their prototypes. These prototypes were tested by Gasunie Engineering & Technology. For these tests, a special test facility was built to exchange the heat from the flue gases to a local water circuit, which can release the heat absorbed to a cooling system (see Figure 1). Prototype heat exchanger to be tested TIC pump 3-way control valve Plate heat exchanger max. 200 kWth T in: 70°C T out: 90°C flow: 5.6 – 6.2 m3/h Cooling water supply Cooling water discharge Flue gas from microturbine Figure 1 Test rig for prototype heat exchangers A water circuit including a pump, a three-way control valve and a plate heat exchanger (to withdraw the heat transferred out of the flue gases to the water) was constructed to define the flow and temperature of the incoming water to the prototype.PDF Image | DEMONSTRATION OF CAPSTONE MICROTURBINES INCLUDING HIGH EFFICIENCY HEAT EXCHANGER, GAS SAFEGUARD MODULE AND NATURAL GAS COMPRESSOR, DEVELOPED BY GASUNIE ENGINEERING & TECHNOLOGY

PDF Search Title:

DEMONSTRATION OF CAPSTONE MICROTURBINES INCLUDING HIGH EFFICIENCY HEAT EXCHANGER, GAS SAFEGUARD MODULE AND NATURAL GAS COMPRESSOR, DEVELOPED BY GASUNIE ENGINEERING & TECHNOLOGYOriginal File Name Searched:

add10459.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |