PDF Publication Title:

Text from PDF Page: 033

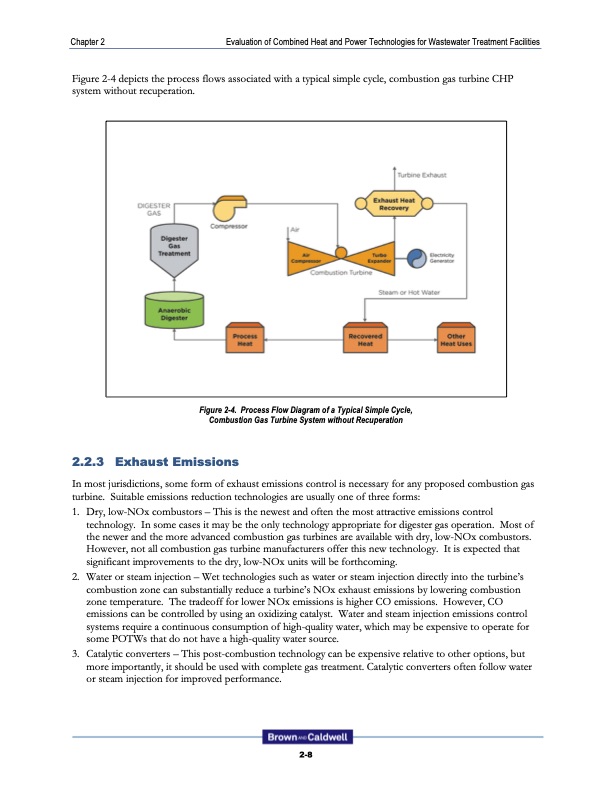

Chapter 2 Evaluation of Combined Heat and Power Technologies for Wastewater Treatment Facilities Figure 2-4 depicts the process flows associated with a typical simple cycle, combustion gas turbine CHP system without recuperation. Figure 2-4. Process Flow Diagram of a Typical Simple Cycle, Combustion Gas Turbine System without Recuperation 2.2.3 Exhaust Emissions In most jurisdictions, some form of exhaust emissions control is necessary for any proposed combustion gas turbine. Suitable emissions reduction technologies are usually one of three forms: 1. Dry,low-NOxcombustors–Thisisthenewestandoftenthemostattractiveemissionscontrol technology. In some cases it may be the only technology appropriate for digester gas operation. Most of the newer and the more advanced combustion gas turbines are available with dry, low-NOx combustors. However, not all combustion gas turbine manufacturers offer this new technology. It is expected that significant improvements to the dry, low-NOx units will be forthcoming. 2. Waterorsteaminjection–Wettechnologiessuchaswaterorsteaminjectiondirectlyintotheturbine’s combustion zone can substantially reduce a turbine’s NOx exhaust emissions by lowering combustion zone temperature. The tradeoff for lower NOx emissions is higher CO emissions. However, CO emissions can be controlled by using an oxidizing catalyst. Water and steam injection emissions control systems require a continuous consumption of high-quality water, which may be expensive to operate for some POTWs that do not have a high-quality water source. 3. Catalyticconverters–Thispost-combustiontechnologycanbeexpensiverelativetootheroptions,but more importantly, it should be used with complete gas treatment. Catalytic converters often follow water or steam injection for improved performance. 2-8PDF Image | Combined Heat and Power Technologies for Wastewater Facilities

PDF Search Title:

Combined Heat and Power Technologies for Wastewater FacilitiesOriginal File Name Searched:

300_CHP-EPA-w-Apps.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |