PDF Publication Title:

Text from PDF Page: 029

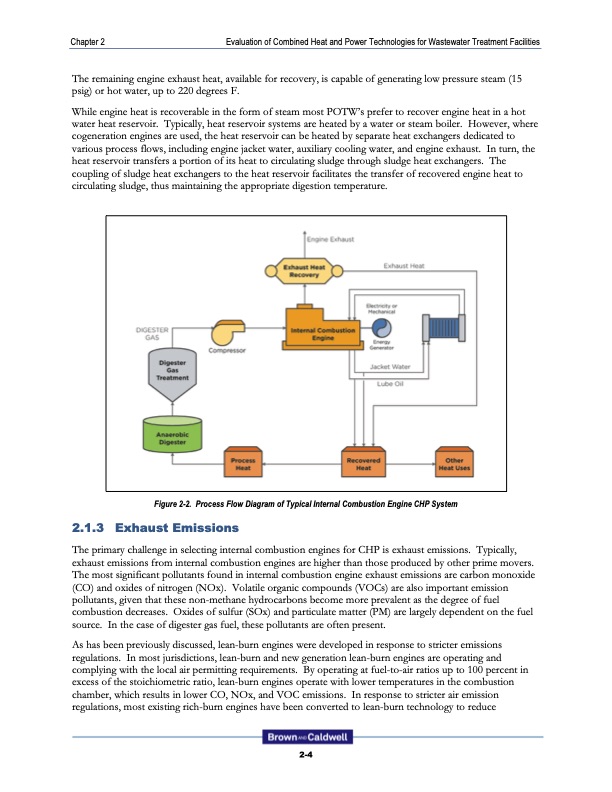

Chapter 2 Evaluation of Combined Heat and Power Technologies for Wastewater Treatment Facilities The remaining engine exhaust heat, available for recovery, is capable of generating low pressure steam (15 psig) or hot water, up to 220 degrees F. While engine heat is recoverable in the form of steam most POTW’s prefer to recover engine heat in a hot water heat reservoir. Typically, heat reservoir systems are heated by a water or steam boiler. However, where cogeneration engines are used, the heat reservoir can be heated by separate heat exchangers dedicated to various process flows, including engine jacket water, auxiliary cooling water, and engine exhaust. In turn, the heat reservoir transfers a portion of its heat to circulating sludge through sludge heat exchangers. The coupling of sludge heat exchangers to the heat reservoir facilitates the transfer of recovered engine heat to circulating sludge, thus maintaining the appropriate digestion temperature. Figure 2-2. Process Flow Diagram of Typical Internal Combustion Engine CHP System 2.1.3 Exhaust Emissions The primary challenge in selecting internal combustion engines for CHP is exhaust emissions. Typically, exhaust emissions from internal combustion engines are higher than those produced by other prime movers. The most significant pollutants found in internal combustion engine exhaust emissions are carbon monoxide (CO) and oxides of nitrogen (NOx). Volatile organic compounds (VOCs) are also important emission pollutants, given that these non-methane hydrocarbons become more prevalent as the degree of fuel combustion decreases. Oxides of sulfur (SOx) and particulate matter (PM) are largely dependent on the fuel source. In the case of digester gas fuel, these pollutants are often present. As has been previously discussed, lean-burn engines were developed in response to stricter emissions regulations. In most jurisdictions, lean-burn and new generation lean-burn engines are operating and complying with the local air permitting requirements. By operating at fuel-to-air ratios up to 100 percent in excess of the stoichiometric ratio, lean-burn engines operate with lower temperatures in the combustion chamber, which results in lower CO, NOx, and VOC emissions. In response to stricter air emission regulations, most existing rich-burn engines have been converted to lean-burn technology to reduce 2-4PDF Image | Combined Heat and Power Technologies for Wastewater Facilities

PDF Search Title:

Combined Heat and Power Technologies for Wastewater FacilitiesOriginal File Name Searched:

300_CHP-EPA-w-Apps.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |