PDF Publication Title:

Text from PDF Page: 002

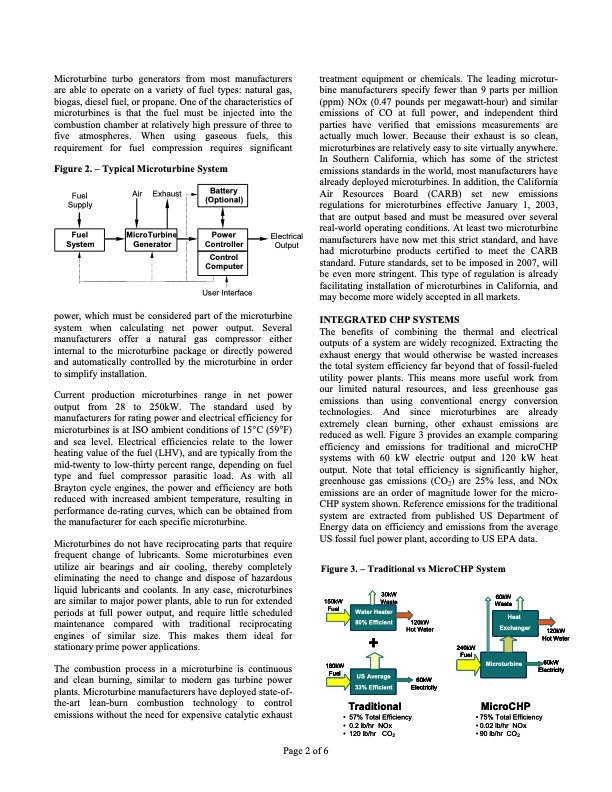

Microturbine turbo generators from most manufacturers are able to operate on a variety of fuel types: natural gas, biogas, diesel fuel, or propane. One of the characteristics of microturbines is that the fuel must be injected into the combustion chamber at relatively high pressure of three to five atmospheres. When using gaseous fuels, this requirement for fuel compression requires significant treatment equipment or chemicals. The leading microtur- bine manufacturers specify fewer than 9 parts per million (ppm) NOx (0.47 pounds per megawatt-hour) and similar emissions of CO at full power, and independent third parties have verified that emissions measurements are actually much lower. Because their exhaust is so clean, microturbines are relatively easy to site virtually anywhere. In Southern California, which has some of the strictest emissions standards in the world, most manufacturers have already deployed microturbines. In addition, the California Air Resources Board (CARB) set new emissions regulations for microturbines effective January 1, 2003, that are output based and must be measured over several real-world operating conditions. At least two microturbine manufacturers have now met this strict standard, and have had microturbine products certified to meet the CARB standard. Future standards, set to be imposed in 2007, will be even more stringent. This type of regulation is already facilitating installation of microturbines in California, and may become more widely accepted in all markets. INTEGRATED CHP SYSTEMS The benefits of combining the thermal and electrical outputs of a system are widely recognized. Extracting the exhaust energy that would otherwise be wasted increases the total system efficiency far beyond that of fossil-fueled utility power plants. This means more useful work from our limited natural resources, and less greenhouse gas emissions than using conventional energy conversion technologies. And since microturbines are already extremely clean burning, other exhaust emissions are reduced as well. Figure 3 provides an example comparing efficiency and emissions for traditional and microCHP systems with 60 kW electric output and 120 kW heat output. Note that total efficiency is significantly higher, greenhouse gas emissions (CO2) are 25% less, and NOx emissions are an order of magnitude lower for the micro- CHP system shown. Reference emissions for the traditional system are extracted from published US Department of Energy data on efficiency and emissions from the average US fossil fuel power plant, according to US EPA data. Figure 2. – Typical Microturbine System Fuel Supply Air Exhaust MicroTurbine Generator Power Controller Control Computer Fuel System power, which must be considered part of the microturbine system when calculating net power output. Several manufacturers offer a natural gas compressor either internal to the microturbine package or directly powered and automatically controlled by the microturbine in order to simplify installation. Current production microturbines range in net power output from 28 to 250kW. The standard used by manufacturers for rating power and electrical efficiency for microturbines is at ISO ambient conditions of 15°C (59°F) and sea level. Electrical efficiencies relate to the lower heating value of the fuel (LHV), and are typically from the mid-twenty to low-thirty percent range, depending on fuel type and fuel compressor parasitic load. As with all Brayton cycle engines, the power and efficiency are both reduced with increased ambient temperature, resulting in performance de-rating curves, which can be obtained from the manufacturer for each specific microturbine. Microturbines do not have reciprocating parts that require frequent change of lubricants. Some microturbines even utilize air bearings and air cooling, thereby completely eliminating the need to change and dispose of hazardous liquid lubricants and coolants. In any case, microturbines are similar to major power plants, able to run for extended periods at full power output, and require little scheduled maintenance compared with traditional reciprocating engines of similar size. This makes them ideal for stationary prime power applications. The combustion process in a microturbine is continuous and clean burning, similar to modern gas turbine power plants. Microturbine manufacturers have deployed state-of- the-art lean-burn combustion technology to control emissions without the need for expensive catalytic exhaust Figure 3. – Traditional vs MicroCHP System Battery (Optional) User Interface Electrical Output 30kW Waste + Electricity Traditional • 57% Total Efficiency • 0.2 lb/hr NOx • 120 lb/hr CO2 60kW Waste MicroCHP 150kW Fuel 180kW Fuel 120kW Hot Water 120kW Hot Water 60kW Electricity Page 2 of 6 Water Heater 80% Efficient 60kW 240kW Fuel Heat Exchanger Microturbine US Average 33% Efficient • 75% Total Efficiency • 0.02 lb/hr NOx • 90 lb/hr CO2PDF Image | CHP Case Studies – Saving Money and Increasing Security

PDF Search Title:

CHP Case Studies – Saving Money and Increasing SecurityOriginal File Name Searched:

micoturbines.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |