PDF Publication Title:

Text from PDF Page: 004

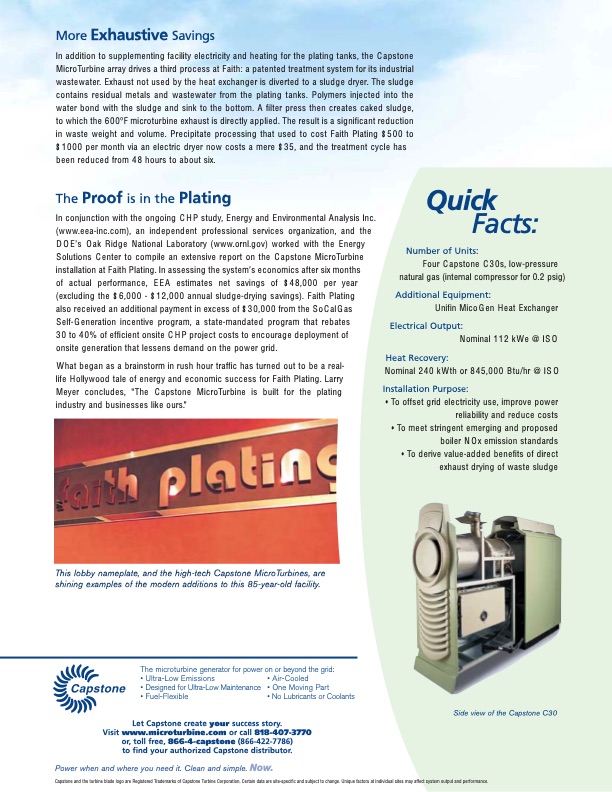

More Exhaustive Savings In addition to supplementing facility electricity and heating for the plating tanks, the Capstone MicroTurbine array drives a third process at Faith: a patented treatment system for its industrial wastewater. Exhaust not used by the heat exchanger is diverted to a sludge dryer. The sludge contains residual metals and wastewater from the plating tanks. Polymers injected into the water bond with the sludge and sink to the bottom. A filter press then creates caked sludge, to which the 600oF microturbine exhaust is directly applied. The result is a significant reduction in waste weight and volume. Precipitate processing that used to cost Faith Plating $500 to $1000 per month via an electric dryer now costs a mere $35, and the treatment cycle has been reduced from 48 hours to about six. The Proof is in the Plating In conjunction with the ongoing CHP study, Energy and Environmental Analysis Inc. (www.eea-inc.com), an independent professional services organization, and the DOE’s Oak Ridge National Laboratory (www.ornl.gov) worked with the Energy Solutions Center to compile an extensive report on the Capstone MicroTurbine installation at Faith Plating. In assessing the system’s economics after six months of actual performance, EEA estimates net savings of $48,000 per year (excluding the $6,000 - $12,000 annual sludge-drying savings). Faith Plating also received an additional payment in excess of $30,000 from the SoCalGas Self-Generation incentive program, a state-mandated program that rebates 30 to 40% of efficient onsite CHP project costs to encourage deployment of onsite generation that lessens demand on the power grid. What began as a brainstorm in rush hour traffic has turned out to be a real- life Hollywood tale of energy and economic success for Faith Plating. Larry Meyer concludes, “The Capstone MicroTurbine is built for the plating industry and businesses like ours.” Quick Facts: Number of Units: Four Capstone C30s, low-pressure natural gas (internal compressor for 0.2 psig) Additional Equipment: Unifin MicoGen Heat Exchanger Electrical Output: Nominal 112 kWe @ ISO Nominal 240 kWth or 845,000 Btu/hr @ ISO Installation Purpose: • To offset grid electricity use, improve power reliability and reduce costs • To meet stringent emerging and proposed boiler NOx emission standards • To derive value-added benefits of direct exhaust drying of waste sludge Heat Recovery: This lobby nameplate, and the high-tech Capstone MicroTurbines, are shining examples of the modern additions to this 85-year-old facility. The microturbine generator for power on or beyond the grid: • Ultra-Low Emissions • Designed for Ultra-Low Maintenance • Fuel-Flexible • Air-Cooled • One Moving Part • No Lubricants or Coolants Let Capstone create your success story. Visit www.microturbine.com or call 818-407-3770 or, toll free, 866-4-capstone (866-422-7786) to find your authorized Capstone distributor. Power when and where you need it. Clean and simple. Now. Capstone and the turbine blade logo are Registered Trademarks of Capstone Turbine Corporation. Certain data are site-specific and subject to change. Unique factors at individual sites may affect system output and performance. Side view of the Capstone C30PDF Image | Capstone MicroTurbines Address Cost, Emission and Power Reliability Issues at a Classic Hollywood Metal Plating Facility

PDF Search Title:

Capstone MicroTurbines Address Cost, Emission and Power Reliability Issues at a Classic Hollywood Metal Plating FacilityOriginal File Name Searched:

Capstone_CS_MetalPlating.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |